More Money Than Brains

#283

Iím using my NA throttle body with the air tube. You might consider going to whatever big box parts store you like (Napa is my go-to) and raiding their molded hoses for something that will fit. I found a pretty nice 3/4Ē hose that was molded into a Z, it would probably clear the sharp turn around the intercooler pipe at the top.

#284

Went from this old piece of ****

To this--much better

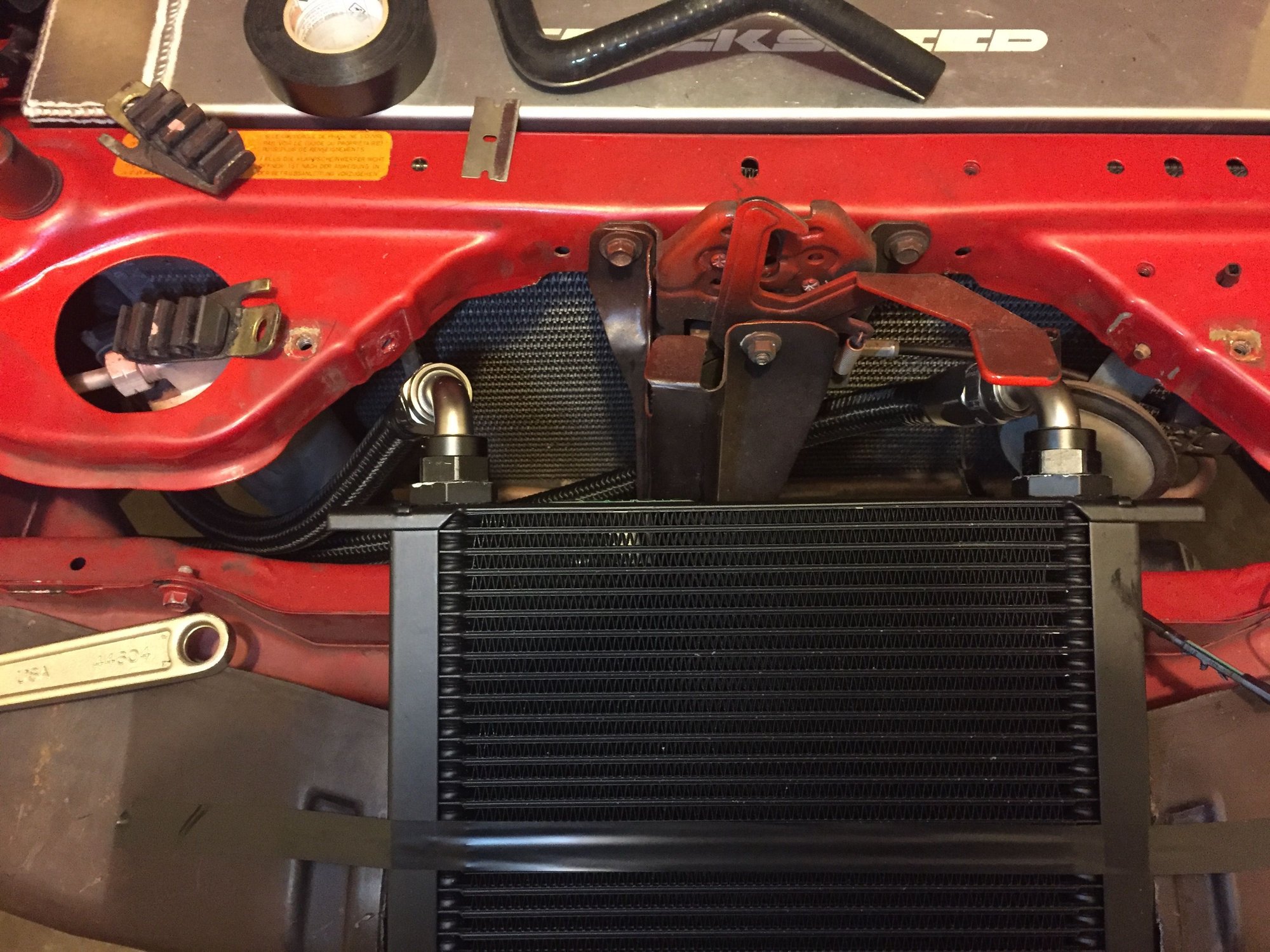

Spent an eternity trying to figure out where to mount my oil cooler. I have a 25 row and the reality is its a big bitch and with leaving the A/C it sorta limited options so I settled on this as Sixshooter had success with.

Managed to make the custom AN hoses without too much fuss.

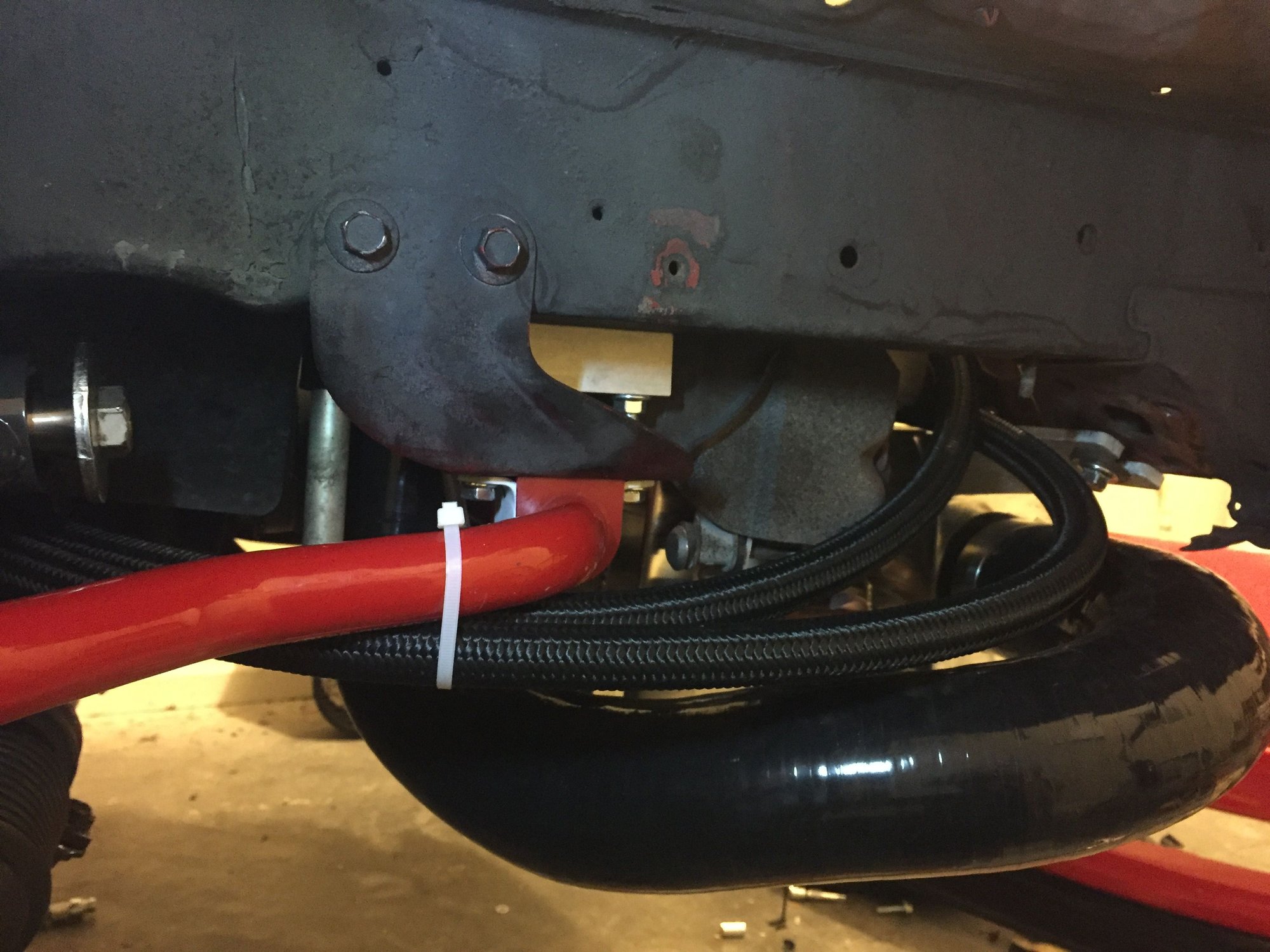

View from below

This is from above just to show there is space above it for air to flow. I can get my hand above it -- its tight but I think with some ducting I should get adequate flow across it. Im hoping with the 25 row there will be a little redundancy since its obviously not 100% ideal but sadly its all I could figure out for placement.

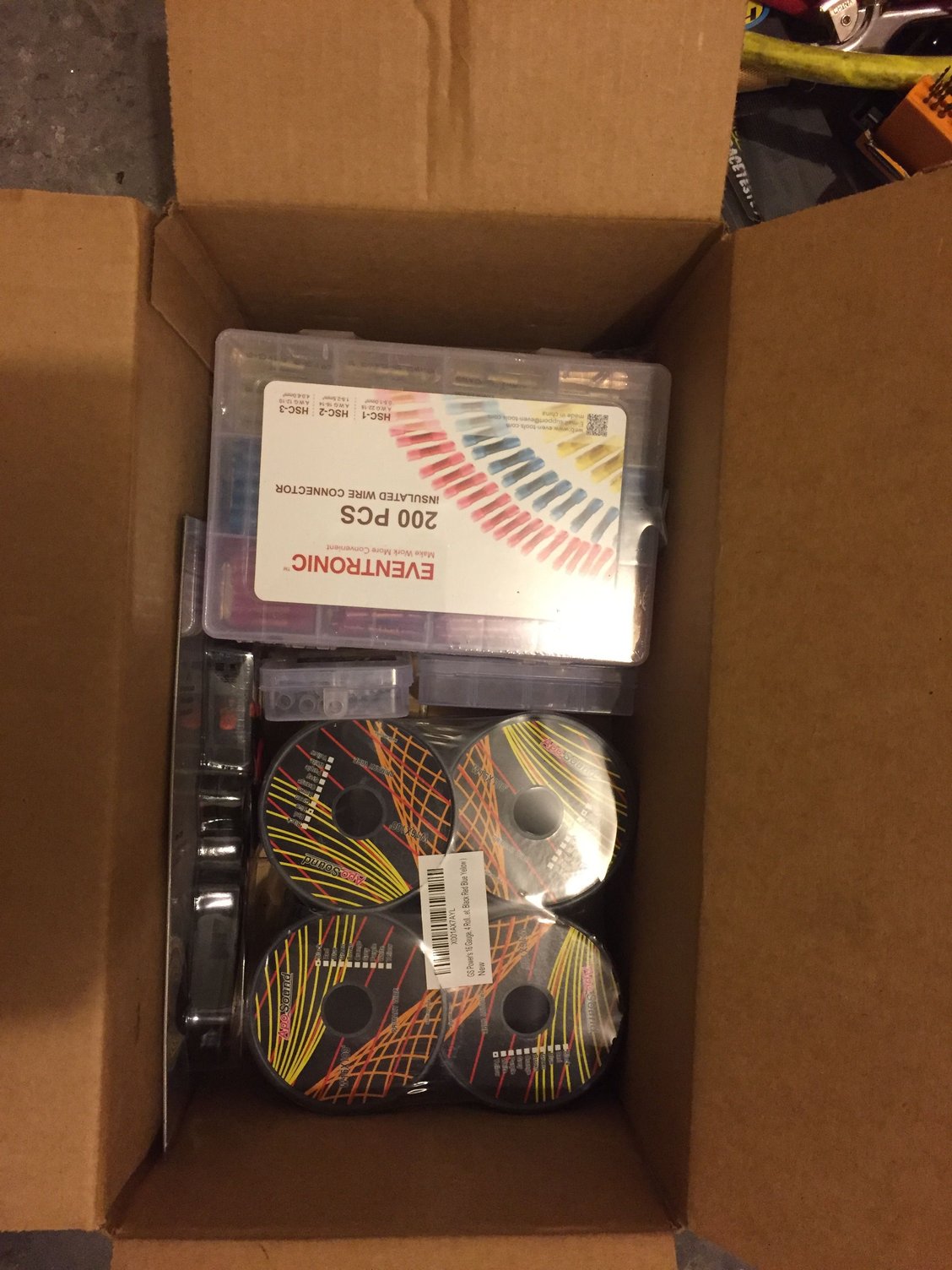

Got a box of wires and ****

Stared at this for a while--realized I don't know **** about wiring--swallowed sadness. Basically need to figure out how to rewire this thing for my new injectors, my wideband, and just generally make it not look like a pile o ****. Also need to figure out what comes off this thing and see if there is any other wiring to be done. Also need to wire the knock sensor and splice in the trigger wheel sensor since I added that. Progress Im sure will be slow because I really don't know this part at all...be patient because I want it to look nice but also don't want to **** it up royally. After that I think Im really close to trying to start the car. Have to plug in the MS and do a little work figuring out the racepak dash but once I get this harness figured out I think I can put fluids in the car and try and start her. Im getting pretty excited -- just have to struggle through this part. There are other little odds and ends but thats where Im at.

This part showed up too

Just waiting on the ABS sensor and then add that to the list of **** to figure out. It'll be fun and a bitch all at the same time.

#293

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,814

Total Cats: 3,051

Maybe I am wrong. We've had some machinery that operates in signals measured in milliamps that have been affected negatively by the additional resistance of butt connectors rather than soldering.

#296

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,814

Total Cats: 3,051

I thought it was because OEMs were forced to use shitty tin solder instead of lead. There happen to be plenty of wires that are soldered to circuit boards in Toyotas and in all of Brain's Megasquirts.

#297

These are expensive, but I really like them:

26-20 AWG TIN PLATED HEAT-SHRINK BUTT SPLICES from Aircraft Spruce

TonyMontana can afford them.

26-20 AWG TIN PLATED HEAT-SHRINK BUTT SPLICES from Aircraft Spruce

TonyMontana can afford them.

#298

Senior Member

iTrader: (1)

Join Date: Dec 2010

Location: Farmington Hills, MI

Posts: 1,218

Total Cats: 175

One of the most debated topics on the internet! In general, crimp > solder, because solder is brittle and can crack. But, in the amateur world, use whatever you are more skilled at. A good strain relieved and heat shrunk solder joint would be more reliable than a half assed crimp joint. But it's worth learning to crimp properly. I use uninsulated crimps with glue lined heat shrink like these. Can't get much more OEM looking!

#300

Sorry to ignite a more general debate here. I was more or less comparing cheap, unknown heat-shrink butt splices with high-quality heat-shrink butt splices from TE, Molex, or 3M. The biggest difference is that nice closed-barrel splices have a strong brazed seam that is necessary for good performance with hand crimping tools.

There are many right ways to splice wires, many wrong ways, and lots of opinions. However, itís generally reasonable to buy high quality versions of whatever method youíve chosen and to use a good crimp tool. Plus, nice butt splices come in step-down versions perfect for changing wire gauges or fanning out a signal to multiple wires.

It's surprisingly inexpensive to have branded tooling to match, which gives good confidence of a high-quality result.

Molex heat-shrink butt splice crimp tool ($57)

Molex 22-18awg heat-shrink butt splice ($0.19)

Molex 16-14awg heat-shrink butt splice ($0.21)

Molex step-down 22-18/16-14awg heat-shrink butt splice ($0.46)

There are many right ways to splice wires, many wrong ways, and lots of opinions. However, itís generally reasonable to buy high quality versions of whatever method youíve chosen and to use a good crimp tool. Plus, nice butt splices come in step-down versions perfect for changing wire gauges or fanning out a signal to multiple wires.

It's surprisingly inexpensive to have branded tooling to match, which gives good confidence of a high-quality result.

Molex heat-shrink butt splice crimp tool ($57)

Molex 22-18awg heat-shrink butt splice ($0.19)

Molex 16-14awg heat-shrink butt splice ($0.21)

Molex step-down 22-18/16-14awg heat-shrink butt splice ($0.46)