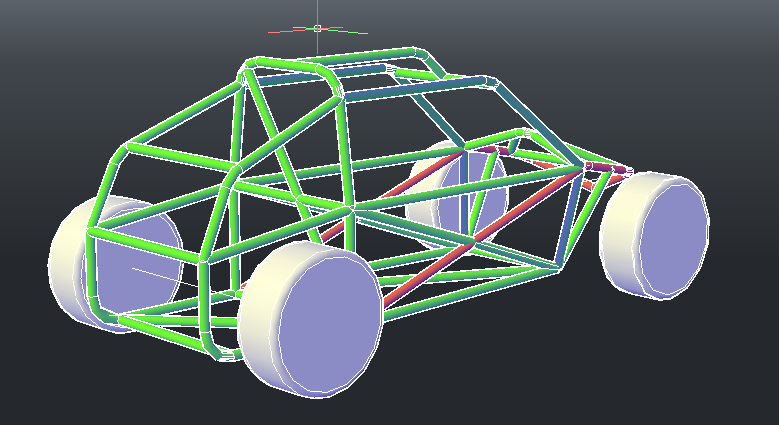

Miata Based, Mid Engine, Single Seat Tube Chassis Build

#1

Hi all,

So this is the first build thread I've done, and will be slowly updating as things happen. It may be slow at times but I plan to complete the build this year.. We'll see.

The BUILD:

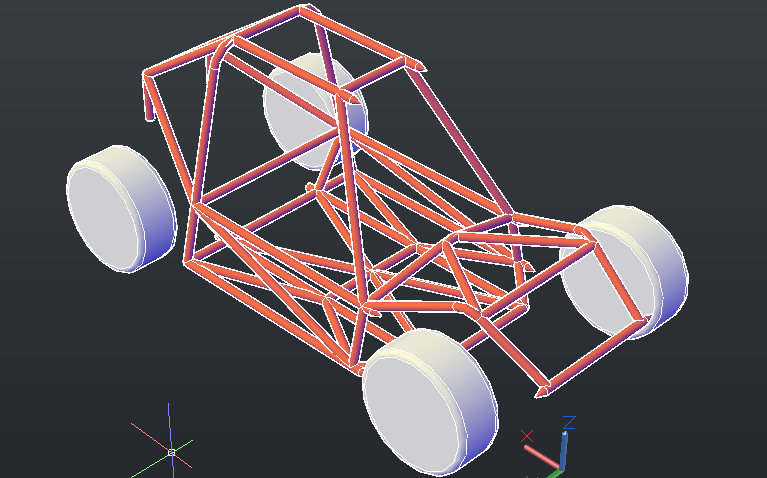

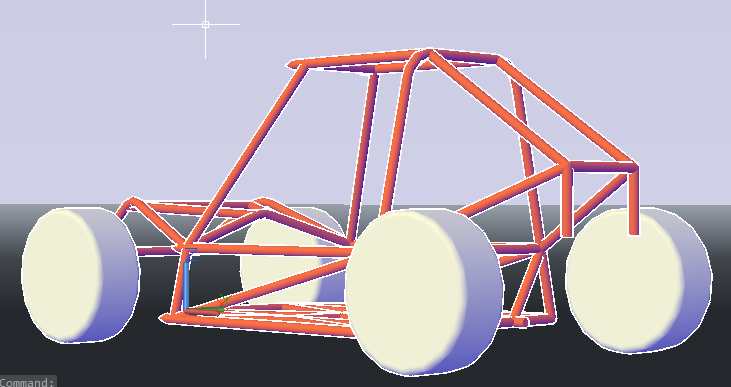

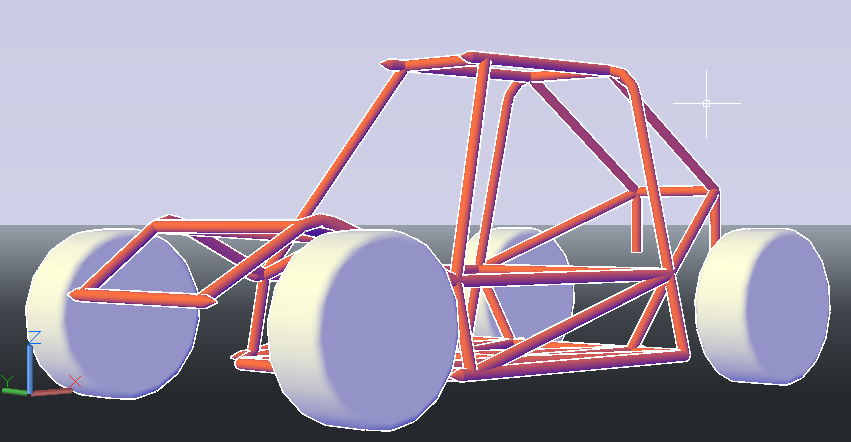

This build started as a spit-balling, dreaming idea of a homebuilt Ariel Atom-esque car with my father. The idea goes something like;

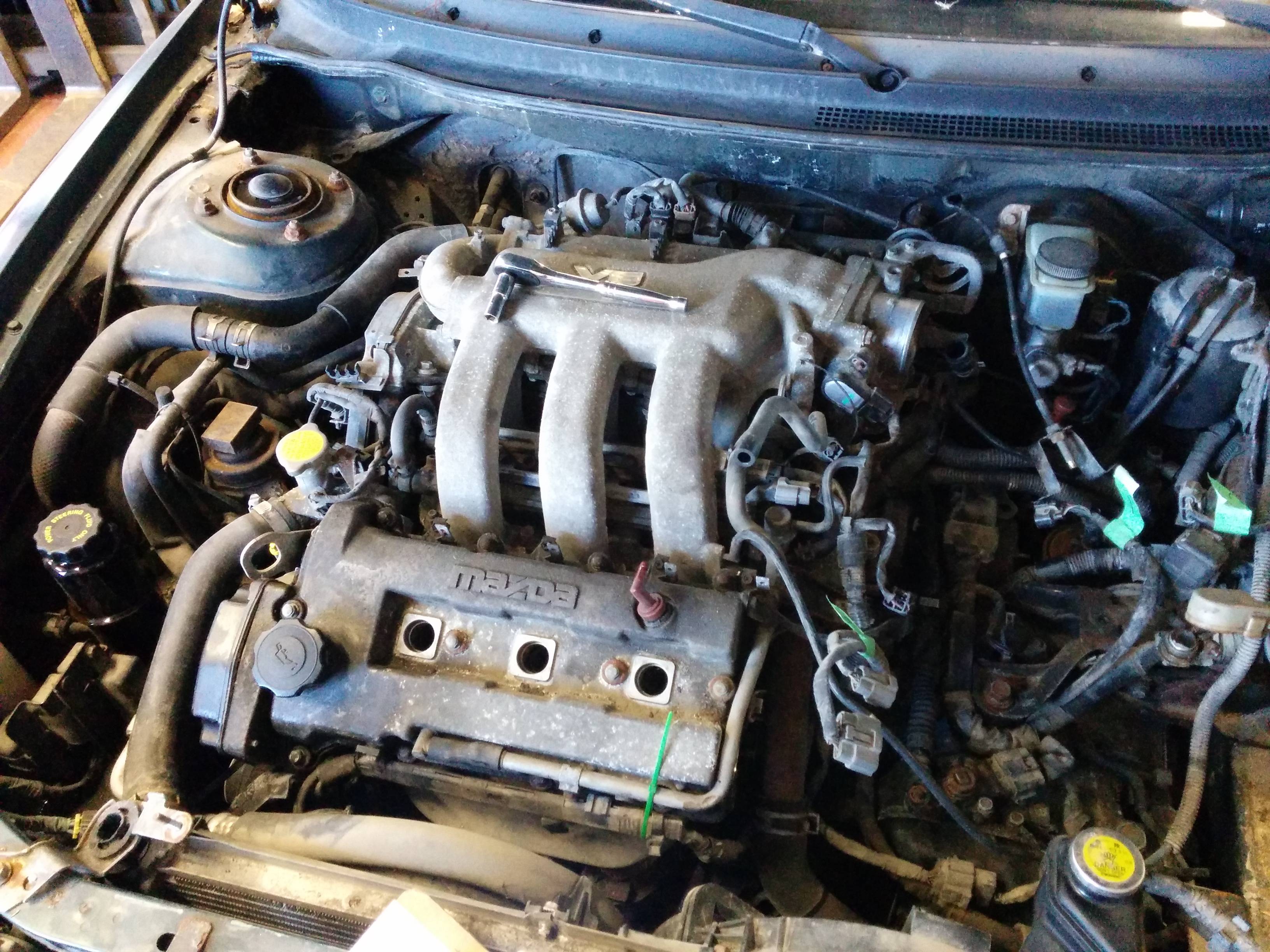

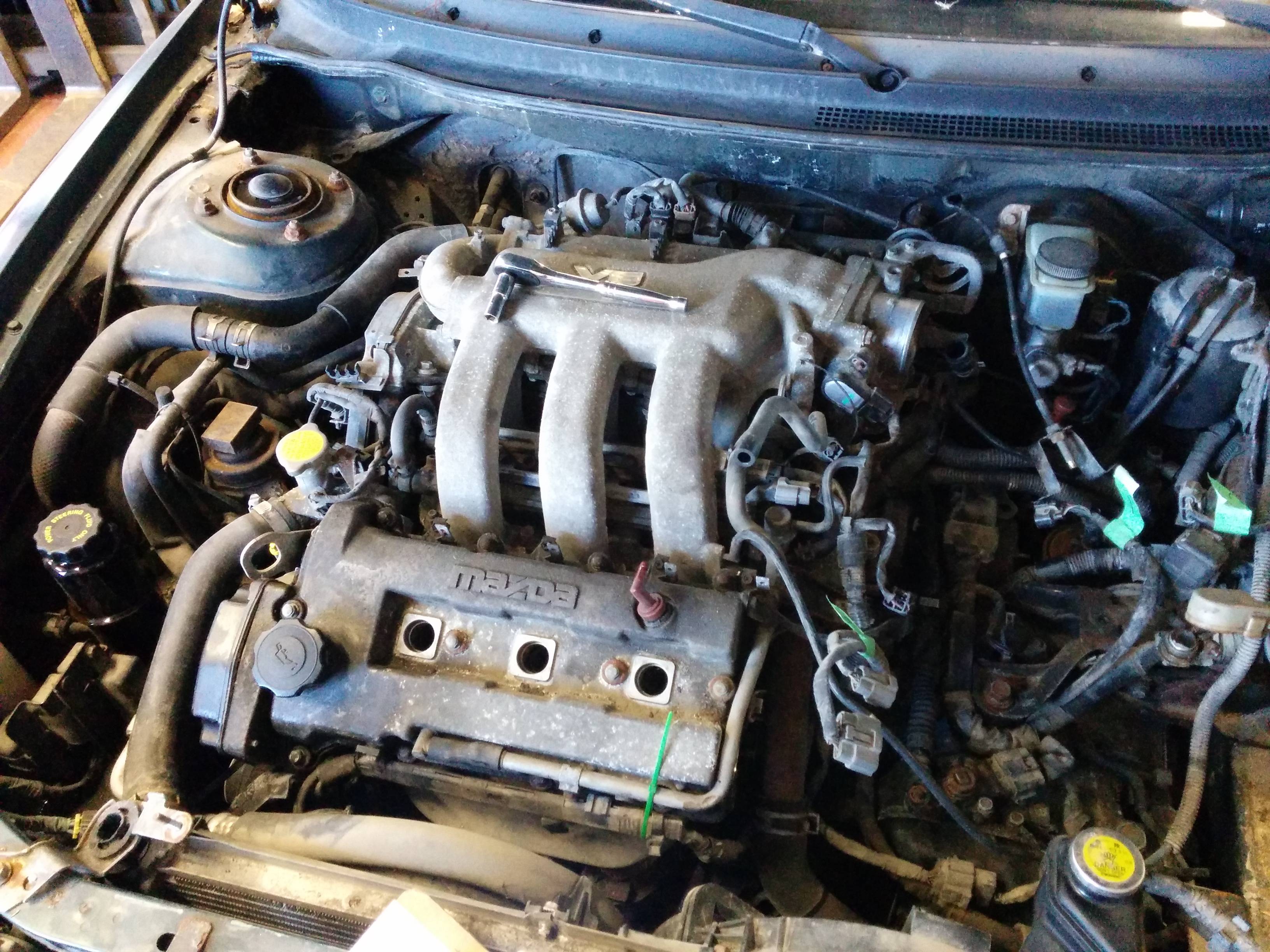

-KL series motor.

-MX3 transaxle.

-Unaltered Miata front subframe (in Exocet fashion).

-Modified Miata rear subframe to house engine and transaxle.

-Tube chassis and single centred seat connecting front and rear.

-80" Wheelbase.

It was a bit of a crazy idea, but out of curiousity I made a parts list with prices, and guestimated I could build it for a not too terrible price.

Then I decided I was going to do it.

So I bought a Mazda 626 Cronos for its KLDE and wiring harness. It had over 200,000 km, but I paid $200 for a running car. Less than I estimated for the engine.

And pulled the motor.

And the harness too.

Then after talking with another local Miata racer, I scored this 2001 rolling chassis.

Along the way I also bought used MX3 transaxle, axles, clutch, flywheel and pressure plate.

This afternoon I am heading to a friend and cage builder of mine to discuss and begin building the chassis. I have a truck load of subframes, an engine, trans, etc..

Early prediction is the engine and trans will not work with the rear subframe no matter how much modification. It will likely mean custom control arms to mount around the drivetrain, or infront or behind.

I'm slowly trying to turn this day dream into a reality.

So this is the first build thread I've done, and will be slowly updating as things happen. It may be slow at times but I plan to complete the build this year.. We'll see.

The BUILD:

This build started as a spit-balling, dreaming idea of a homebuilt Ariel Atom-esque car with my father. The idea goes something like;

-KL series motor.

-MX3 transaxle.

-Unaltered Miata front subframe (in Exocet fashion).

-Modified Miata rear subframe to house engine and transaxle.

-Tube chassis and single centred seat connecting front and rear.

-80" Wheelbase.

It was a bit of a crazy idea, but out of curiousity I made a parts list with prices, and guestimated I could build it for a not too terrible price.

Then I decided I was going to do it.

So I bought a Mazda 626 Cronos for its KLDE and wiring harness. It had over 200,000 km, but I paid $200 for a running car. Less than I estimated for the engine.

And pulled the motor.

And the harness too.

Then after talking with another local Miata racer, I scored this 2001 rolling chassis.

Along the way I also bought used MX3 transaxle, axles, clutch, flywheel and pressure plate.

This afternoon I am heading to a friend and cage builder of mine to discuss and begin building the chassis. I have a truck load of subframes, an engine, trans, etc..

Early prediction is the engine and trans will not work with the rear subframe no matter how much modification. It will likely mean custom control arms to mount around the drivetrain, or infront or behind.

I'm slowly trying to turn this day dream into a reality.

#2

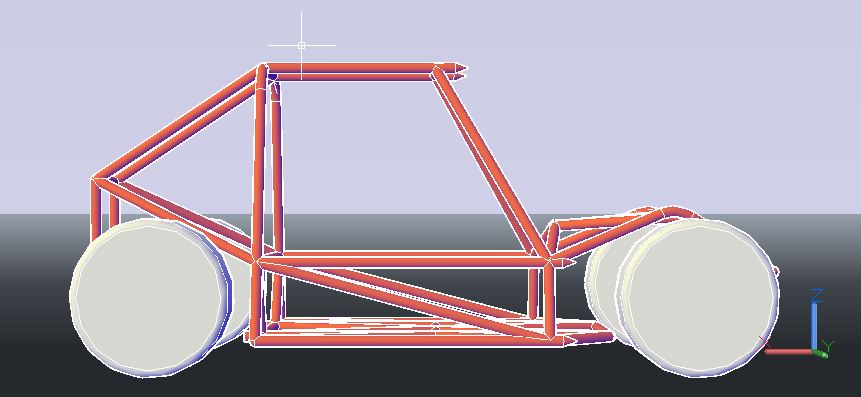

I've debated with myself what wheelbase the chassis will be built on. I believe I can fit it all into 80", which would be great for things like AutoX events, but make it a handful if I were to do something like a lapping day on track. Miata stock is something like 89.4", I'm considering possibly something in between the two..

#5

This is a one day project of mine. Good luck and I'm looking forward to seeing how it goes. 80" puts it at about the same dimensions as the Palatov D1/D4 (dp vehicle home) which seems to work pretty well for him. Longer would probably be aerodynamically better if you were doing body panels.

If it's a track car have you thought about a proper transaxle? These cars don't have a lot of power and are gearing sensitive on track. If I drop a BP into a midengined car I'd want a Hewland Mk9 or something behind it, where I could get exactly the gearing I want.

If it's a track car have you thought about a proper transaxle? These cars don't have a lot of power and are gearing sensitive on track. If I drop a BP into a midengined car I'd want a Hewland Mk9 or something behind it, where I could get exactly the gearing I want.

#7

Not likely to register for the road, from what I've heard it can be pretty difficult to do in Ontario.

This is a one day project of mine. Good luck and I'm looking forward to seeing how it goes. 80" puts it at about the same dimensions as the Palatov D1/D4 (dp vehicle home) which seems to work pretty well for him. Longer would probably be aerodynamically better if you were doing body panels.

If it's a track car have you thought about a proper transaxle? These cars don't have a lot of power and are gearing sensitive on track. If I drop a BP into a midengined car I'd want a Hewland Mk9 or something behind it, where I could get exactly the gearing I want.

If it's a track car have you thought about a proper transaxle? These cars don't have a lot of power and are gearing sensitive on track. If I drop a BP into a midengined car I'd want a Hewland Mk9 or something behind it, where I could get exactly the gearing I want.

I'll read up on his blog about his experience with ~80" wheel base My only concern is that on track it will be even more difficult to control in the event of the rear end loosing traction. But we'll see.

I'll read up on his blog about his experience with ~80" wheel base My only concern is that on track it will be even more difficult to control in the event of the rear end loosing traction. But we'll see.It is a track toy. Though the gearing isn't ideal, part of my goal with this project is to keep thing as inexpensive as possibly, and briefly looking at the gearbox for sale used, it'd be beyond my price range. I'm hoping that the KL at ~160hp (when new) and a guestimated weight between 1200-1400# with make up for the poor ratios.

#8

If you're building a custom frame with the engine in back why use the front sub frame. Seems you're adding weight and complexity for little value. If you want the geometry, why not fab up a couple brackets and copy the subframe geometry? It's also good, but not fantastic (see people messing with parts to get to the camber an SM7 or similar actually wants, offset hubs, etc).

The Hewlands are pricier, just threw it out as an option. It's also more or less based on a 4spd VW Beetle transmission (which is also and option). I'm assuming that if I get to build one that I'll only get to do so once, so my goal will be to get the nice stuff, even if it adds to the cost.

The Hewlands are pricier, just threw it out as an option. It's also more or less based on a 4spd VW Beetle transmission (which is also and option). I'm assuming that if I get to build one that I'll only get to do so once, so my goal will be to get the nice stuff, even if it adds to the cost.

#10

If you're building a custom frame with the engine in back why use the front sub frame. Seems you're adding weight and complexity for little value. If you want the geometry, why not fab up a couple brackets and copy the subframe geometry? It's also good, but not fantastic (see people messing with parts to get to the camber an SM7 or similar actually wants, offset hubs, etc).

The Hewlands are pricier, just threw it out as an option. It's also more or less based on a 4spd VW Beetle transmission (which is also and option). I'm assuming that if I get to build one that I'll only get to do so once, so my goal will be to get the nice stuff, even if it adds to the cost.

The Hewlands are pricier, just threw it out as an option. It's also more or less based on a 4spd VW Beetle transmission (which is also and option). I'm assuming that if I get to build one that I'll only get to do so once, so my goal will be to get the nice stuff, even if it adds to the cost.

The main reason (and part of what sparked this whole project) I'm choosing to use the Mazda MX3 front hubs are the same as Miata rear hubs. This idea was what put me into the perspective of transverse V6 in a Miata rear subframe. Using no custom transaxles or CV shafts, the drivline will mate to Miata rear uprights.

Not saying there aren't better, more track oriented ways to go about something like this, but I'm aim to have the car running for the price of some midengine transaxles.

I think it's definitely going to be rearward heavy. Spring rates will obviously be a long shot from typical Miata numbers, as well as ideal shock valving.

The weight balance brings up another topic I've debated of tire sizing. Due to being RWD and rear heavy, I believe a staggered tire choice will probably be required. Ideas? Sizes?

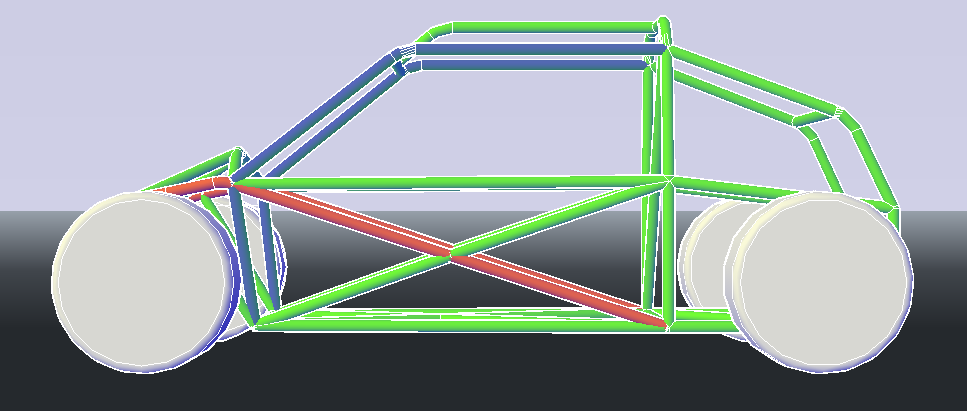

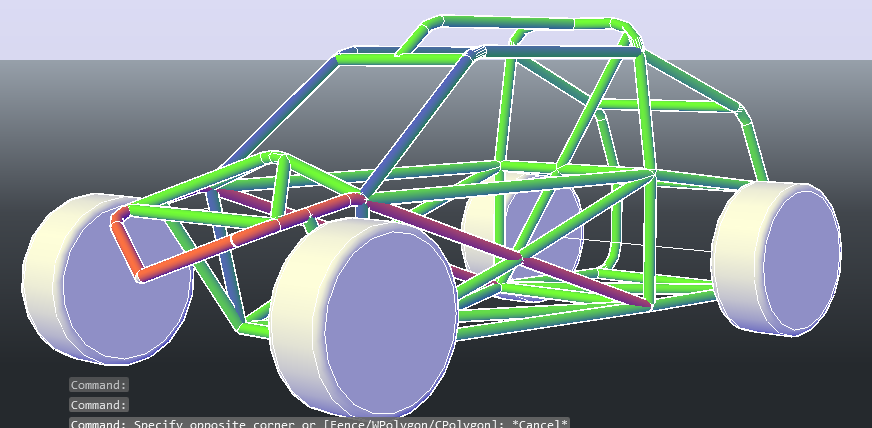

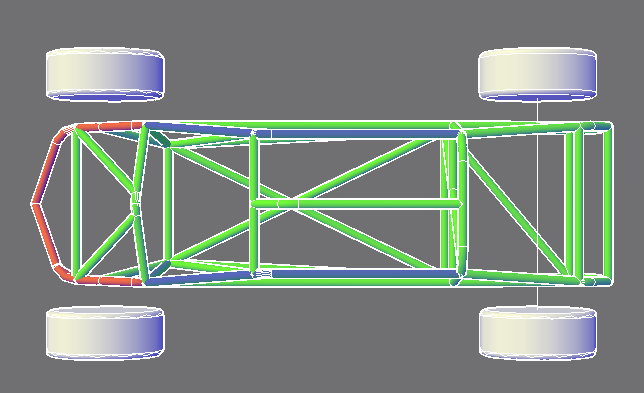

#16

I'd take a long hard look at that before hacking up a bunch of good steel. Looks like a passable roll cage in a marginal frame.

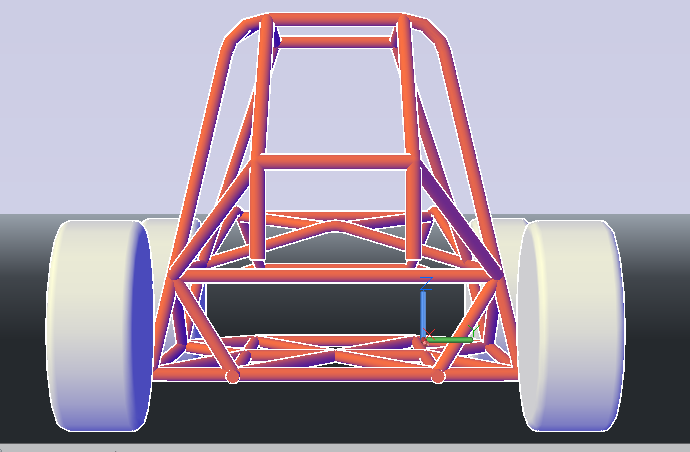

The front of that looks really, really soft. Maybe the subframe will stiffen it up enough, but I suspect the whole thing will just flex around your front cross member. Also, the scale's wacky. Are your feet going to be inside the entire cage with a dash member that's missing? If not that thing's no where near safe to drive. That roll bar may not meet SCCA/NASA spec without a diagonal. Could be wrong, but I think it's a requirement.

The front of that looks really, really soft. Maybe the subframe will stiffen it up enough, but I suspect the whole thing will just flex around your front cross member. Also, the scale's wacky. Are your feet going to be inside the entire cage with a dash member that's missing? If not that thing's no where near safe to drive. That roll bar may not meet SCCA/NASA spec without a diagonal. Could be wrong, but I think it's a requirement.

#17

I'd take a long hard look at that before hacking up a bunch of good steel. Looks like a passable roll cage in a marginal frame.

The front of that looks really, really soft. Maybe the subframe will stiffen it up enough, but I suspect the whole thing will just flex around your front cross member. Also, the scale's wacky. Are your feet going to be inside the entire cage with a dash member that's missing? If not that thing's no where near safe to drive. That roll bar may not meet SCCA/NASA spec without a diagonal. Could be wrong, but I think it's a requirement.

The front of that looks really, really soft. Maybe the subframe will stiffen it up enough, but I suspect the whole thing will just flex around your front cross member. Also, the scale's wacky. Are your feet going to be inside the entire cage with a dash member that's missing? If not that thing's no where near safe to drive. That roll bar may not meet SCCA/NASA spec without a diagonal. Could be wrong, but I think it's a requirement.

I believe the front end will be stiff enough, as you say, the front subframe will box in the front end tubing. I agree there will need to be some tubing added there, though.

There should definitely be a diagonal added to the main hoop. There's a few things that will be added to a final design. This is the basic layout, though.