Luke's "I have an EFR but refuse to use it" Build

#42

Thread Starter

Elite Member

iTrader: (4)

Joined: Sep 2006

Posts: 3,311

Total Cats: 98

From: Charlotte, NC

I received the new thrust bearings and oil pump in the mail yesterday, so assembly of the motor is just waiting on me to make time for it. Naturally the weather has turned so now it's cold in the garage...

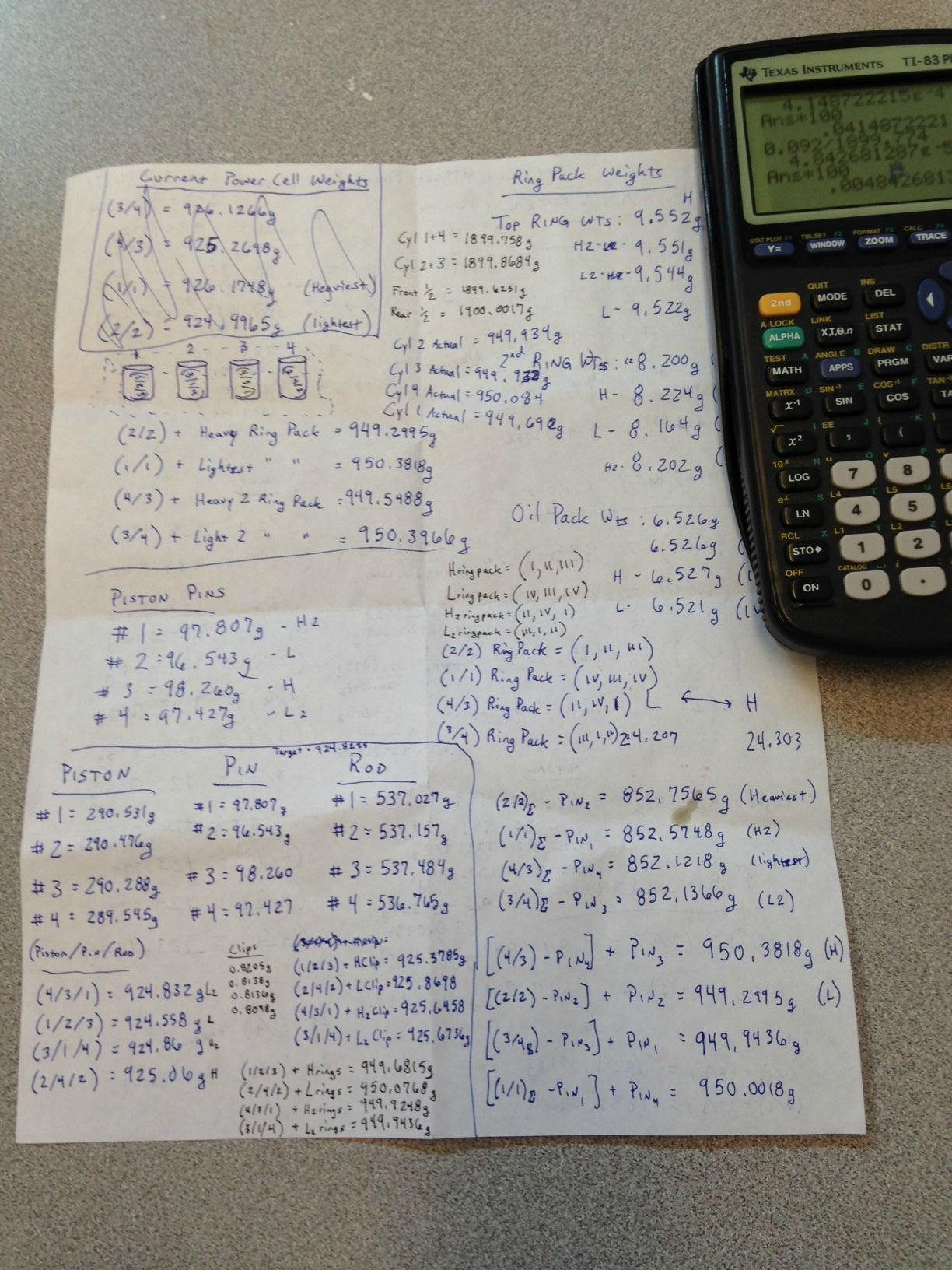

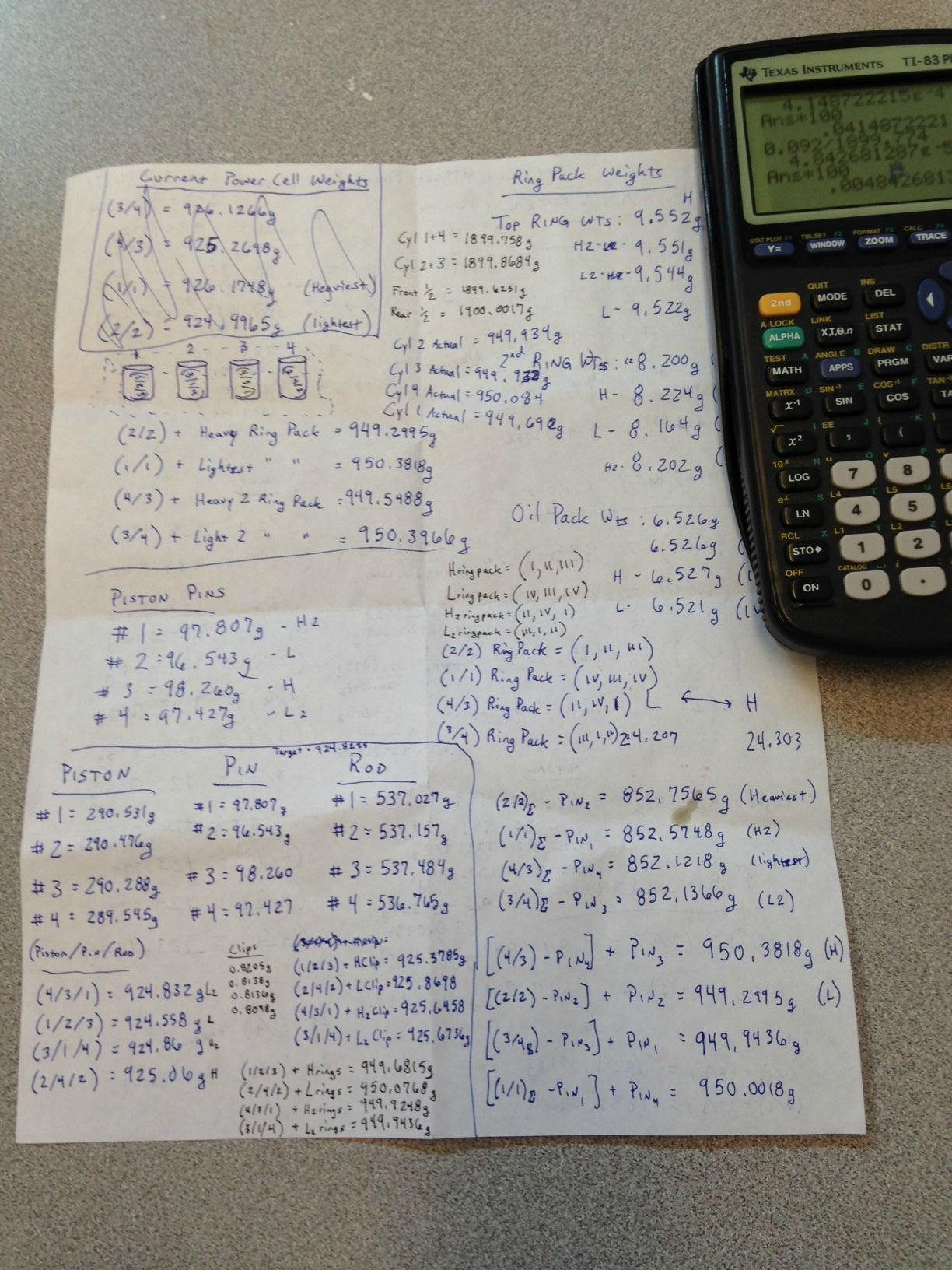

In the mean time I tried to pair up the pistons, rods, pins, ring packs and pin clips to get each cylinder as balanced as possible. I weighed everything on a calibrated laboratory scale and then matched up the various parts to try to get the same weights.

In my OEM world we call the piston, pin, rod, and rings the powercell. So I was trying to get equal powercell weights for each cylinder. Attached is the "worksheet" I made up as I went.

The lightest powercell came out to 949.69g, the heaviest was 950.08g. The other two were both 949.93g. The lightest will go on cylinder 1, the heaviest in cylinder 4. The others will go in 2 and 3. That way the "firing pairs" are extremely balanced.

That was my logic at least. The crankshaft is probably 5+ grams out if balance, but whatever. I had time over my lunch break to weigh the stuff so I figured I might as well try to "balance" everything.

Never mind, picture upload won't work from the phone right meow...

In the mean time I tried to pair up the pistons, rods, pins, ring packs and pin clips to get each cylinder as balanced as possible. I weighed everything on a calibrated laboratory scale and then matched up the various parts to try to get the same weights.

In my OEM world we call the piston, pin, rod, and rings the powercell. So I was trying to get equal powercell weights for each cylinder. Attached is the "worksheet" I made up as I went.

The lightest powercell came out to 949.69g, the heaviest was 950.08g. The other two were both 949.93g. The lightest will go on cylinder 1, the heaviest in cylinder 4. The others will go in 2 and 3. That way the "firing pairs" are extremely balanced.

That was my logic at least. The crankshaft is probably 5+ grams out if balance, but whatever. I had time over my lunch break to weigh the stuff so I figured I might as well try to "balance" everything.

Never mind, picture upload won't work from the phone right meow...

#46

Thread Starter

Elite Member

iTrader: (4)

Joined: Sep 2006

Posts: 3,311

Total Cats: 98

From: Charlotte, NC

I figured having the heaviest in cyl 4 would be best for the cars polar inertia.... Ha!

And yes, the valve cover sanding/polishing isn't going as well as planned. Not really enjoying it. If I can get a really good polish on it I have some very nerdy plans for it.

#47

Sometimes it is just worth the money having these sandblasted.

I started on my intake manifold and a couple hours in just said "**** this" and called my powder coater.

Of course that was after hand grinding and painting 3/4 of my car...so I had hit "the wall" in regards to desire to sand paint etc etc.

I started on my intake manifold and a couple hours in just said "**** this" and called my powder coater.

Of course that was after hand grinding and painting 3/4 of my car...so I had hit "the wall" in regards to desire to sand paint etc etc.

#48

Thread Starter

Elite Member

iTrader: (4)

Joined: Sep 2006

Posts: 3,311

Total Cats: 98

From: Charlotte, NC

Yea, unfortunately I DID sandblast it. But either the shot size was too big or the air pressure was too high or something.

All of the sanding I'm doing now is smoothing out the artifacts of the sand blasting...

All of the sanding I'm doing now is smoothing out the artifacts of the sand blasting...

#50

Thread Starter

Elite Member

iTrader: (4)

Joined: Sep 2006

Posts: 3,311

Total Cats: 98

From: Charlotte, NC

After much ado, the aforementioned "Powercell Weight Calculation Sheet". You probably shouldn't try to follow the logic...

Also finally got around to installing the old wheels and new tires. Gen 1 15x8 6ULs w/ 225/45/15 BFG Rivals. Emilio thinks I'm a huge dbag and thinks I have it out for him on the internetz, but I was one of his first customers and have been supporting his business from the early days. Effing OG 6UL owner.

ALSO, if you were ever wondering if an OEM hardtop will fit in the back of a 2005-2010 Honda Odyssey...it will.

Engine assembly should continue tomorrow morning, might take another morning off of work to get some alone time...

Also finally got around to installing the old wheels and new tires. Gen 1 15x8 6ULs w/ 225/45/15 BFG Rivals. Emilio thinks I'm a huge dbag and thinks I have it out for him on the internetz, but I was one of his first customers and have been supporting his business from the early days. Effing OG 6UL owner.

ALSO, if you were ever wondering if an OEM hardtop will fit in the back of a 2005-2010 Honda Odyssey...it will.

Engine assembly should continue tomorrow morning, might take another morning off of work to get some alone time...

#51

Thread Starter

Elite Member

iTrader: (4)

Joined: Sep 2006

Posts: 3,311

Total Cats: 98

From: Charlotte, NC

Rage posting from phone

RINGS DON'T FIT WORTH A SH"T!?!?!

Like 1.5mm ring gaps.

Me = cornfuzed

At least the new thrust bearings went in fine, and crank end play measured 0.018mm. Right in the center of the OEM spec.

GWAR

RINGS DON'T FIT WORTH A SH"T!?!?!

Like 1.5mm ring gaps.

Me = cornfuzed

At least the new thrust bearings went in fine, and crank end play measured 0.018mm. Right in the center of the OEM spec.

GWAR

#52

DUDEBRO i'm loving your build and all of the updates. Sorry I'm not help with the rings, but with the ST pistons I would go with ST rings. Tried and true with that setup.

Y U NO arp hardware?

Also, which ball hone is that and what grit did you get? Do you want to sell it (considering you outsourced your hone work), I need one for the stock bore size that is the right grit.

Y U NO arp hardware?

Also, which ball hone is that and what grit did you get? Do you want to sell it (considering you outsourced your hone work), I need one for the stock bore size that is the right grit.

Last edited by Fireindc; 03-18-2014 at 01:49 PM.

#53

Thread Starter

Elite Member

iTrader: (4)

Joined: Sep 2006

Posts: 3,311

Total Cats: 98

From: Charlotte, NC

So apparently the 83.5 Supertech pistons I bought are actually 84mm. And the 0.020" overbore I got is actually 0.040"?

My machinist had the pistons when he did the bore job, so he correctly (afaik) bored the block to match the pistons. He just forgot to mention to me they were actually 84mm.

At least I think they are 84mm. I pulled out some calipers and measured the bores and the pistons and I sort of consistently got 83.8-83.9 mm readings.

Closer to 84 then 83.5 I guess...

SO, just ordered some 84mm Supertech rings (Part# GNH8400) from No Limit Motorsports on here, they were great. And the price was very fair, I'm sure well worth the little bit extra cost over the RockAuto stuff.

I hope I can return the other rings, otherwise I'll have bought three sets of rings for this dang build...hahahah....

Oh well, sometimes learning costs a little money.

Just read up on the proper piston to wall clearance for Supertechs...and for turbo track motors. Seems 0.003 - 0.004" is the recommendation. My machinist and I never discussed this so I have no idea what he set them at. Another thing I need to check now and hope (pray?) is OK.

Lots of learning

I'll be at Road Atlanta racing this weekend, so engine build likely won't continue till Monday, maybe later. Dang it

My machinist had the pistons when he did the bore job, so he correctly (afaik) bored the block to match the pistons. He just forgot to mention to me they were actually 84mm.

At least I think they are 84mm. I pulled out some calipers and measured the bores and the pistons and I sort of consistently got 83.8-83.9 mm readings.

Closer to 84 then 83.5 I guess...

SO, just ordered some 84mm Supertech rings (Part# GNH8400) from No Limit Motorsports on here, they were great. And the price was very fair, I'm sure well worth the little bit extra cost over the RockAuto stuff.

I hope I can return the other rings, otherwise I'll have bought three sets of rings for this dang build...hahahah....

Oh well, sometimes learning costs a little money.

Just read up on the proper piston to wall clearance for Supertechs...and for turbo track motors. Seems 0.003 - 0.004" is the recommendation. My machinist and I never discussed this so I have no idea what he set them at. Another thing I need to check now and hope (pray?) is OK.

Lots of learning

I'll be at Road Atlanta racing this weekend, so engine build likely won't continue till Monday, maybe later. Dang it

#54

Thread Starter

Elite Member

iTrader: (4)

Joined: Sep 2006

Posts: 3,311

Total Cats: 98

From: Charlotte, NC

See above post, that's exactly what I did, ordered some ST rings.

Originally Posted by Fireindc

Y U NO arp hardware?

Originally Posted by Fire

Also, which ball hone is that and what grit did you get? Do you want to sell it (considering you outsourced your hone work), I need one for the stock bore size that is the right grit.

$34 shipped if you have Amazon Prime.

I think I want to hold on to this one in case I ever need to "re-hone" a miata motor (which I think is likely).

As for the grit, I'm not really sure if 180 grit (the one I selected) is "the right grit" or not. 240 seemed like it would be too fine, and 120 seemed like it would be too aggressive. That logic was/is based on absolutely no experience or research...

I have more pictures to post but they are A)not very good and B) on my phone which I don't like posting from.

So I'll try to post more pics later for your "benefit"

#58

quoted from 949's website

Why mix and match pistons and rings?

Over the years we have tried just about every piston and ring pack available. We are looking for the same thing you are. Long wear, perfect oil control and of course good power. OEM ring tension is about 15lbs. The NPR rings that Supertech supplies are less than half the ring tension of OEM. That's great for power and lower oil temps but leads to greater oil consumption than OEM. We have found the best overall compromise between power, service life, oil consumption, and oil temps in and OTS (off the shelf) piston and ring is to combine these two brands into one kit. Take advantage of our endurance racing experience. The Wiseco rings cost a few bucks more than the NPR's but they are worth it.

Over the years we have tried just about every piston and ring pack available. We are looking for the same thing you are. Long wear, perfect oil control and of course good power. OEM ring tension is about 15lbs. The NPR rings that Supertech supplies are less than half the ring tension of OEM. That's great for power and lower oil temps but leads to greater oil consumption than OEM. We have found the best overall compromise between power, service life, oil consumption, and oil temps in and OTS (off the shelf) piston and ring is to combine these two brands into one kit. Take advantage of our endurance racing experience. The Wiseco rings cost a few bucks more than the NPR's but they are worth it.

#59

Thread Starter

Elite Member

iTrader: (4)

Joined: Sep 2006

Posts: 3,311

Total Cats: 98

From: Charlotte, NC

Thanks, I researched the wiseco rings.

I'm sure they are great and I don't doubt they are the best available.

How many people have engines with supertech pistons and supertech rings? I'm betting there are a handful on this site, and I've never heard of anyone having excessive oil consumption/blowby/etc.

Also, OEM ring tension was set based on OEM Mazda boring and honing capabilities of 199-whenever. Just because the OEM ring tension is 15 lbs doesn't really mean a whole lot when you have a completely different bore and hone finish.

Emilio (and Sav?) have found that the wiseco's work the best and I believe them because they have built lots of miata motors.

I chose the supertech rings because I'm cheap.

K? thx

I'm sure they are great and I don't doubt they are the best available.

How many people have engines with supertech pistons and supertech rings? I'm betting there are a handful on this site, and I've never heard of anyone having excessive oil consumption/blowby/etc.

Also, OEM ring tension was set based on OEM Mazda boring and honing capabilities of 199-whenever. Just because the OEM ring tension is 15 lbs doesn't really mean a whole lot when you have a completely different bore and hone finish.

Emilio (and Sav?) have found that the wiseco's work the best and I believe them because they have built lots of miata motors.

I chose the supertech rings because I'm cheap.

K? thx