Johnny C from OG racing.. My build thread. LS1 miata..

#21

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#23

about 1"- 2" further forward, i have them sitting on 1X1 steel stock and Howe G3 master cylinders. I can cut the floor pan and put them back to the stock location.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#24

I've done a thing.

Pushed the motor back 2.5", tube the front end, adding a pedal box.

I know my welds suck, these are progress pictures done at the end of every night of work. most of my welds where grounded down and re-done.

the c3 was covered before sparks flew.

more ideas laid out.

finishing the foot box and supporting the upper bars.

yea the welds suck but you get the point. they where ground down and re welded also a gusset will be added.

lots of cutting got me here.

the new fire wall.

the motor goes in-out-in-out

it's a mess but nodes are nodes.

drum roll, the dry sump tank has a home. i'm planning on building the firewall out so i can't access the tank from the inside. this should give me time to get out if there is a fire.

atlas bar.

fire wall was tacked in, it was so humid out it began to rust.

we don't need no stinking fenders.

Pushed the motor back 2.5", tube the front end, adding a pedal box.

I know my welds suck, these are progress pictures done at the end of every night of work. most of my welds where grounded down and re-done.

the c3 was covered before sparks flew.

more ideas laid out.

finishing the foot box and supporting the upper bars.

yea the welds suck but you get the point. they where ground down and re welded also a gusset will be added.

lots of cutting got me here.

the new fire wall.

the motor goes in-out-in-out

it's a mess but nodes are nodes.

drum roll, the dry sump tank has a home. i'm planning on building the firewall out so i can't access the tank from the inside. this should give me time to get out if there is a fire.

atlas bar.

fire wall was tacked in, it was so humid out it began to rust.

we don't need no stinking fenders.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#25

took a few days off to Work a PCA event, cleaned up the garage. and busted out the plasma. made enough room for 2.5" side pipes. they will be covered by the factory side skirts, until the melt. after that i'll figure out something else. maybe make something from bent aluminum.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#28

I used a spec miata rad and just used a aluminum pipe as a cross over. I'll post pictures when I'm done.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#30

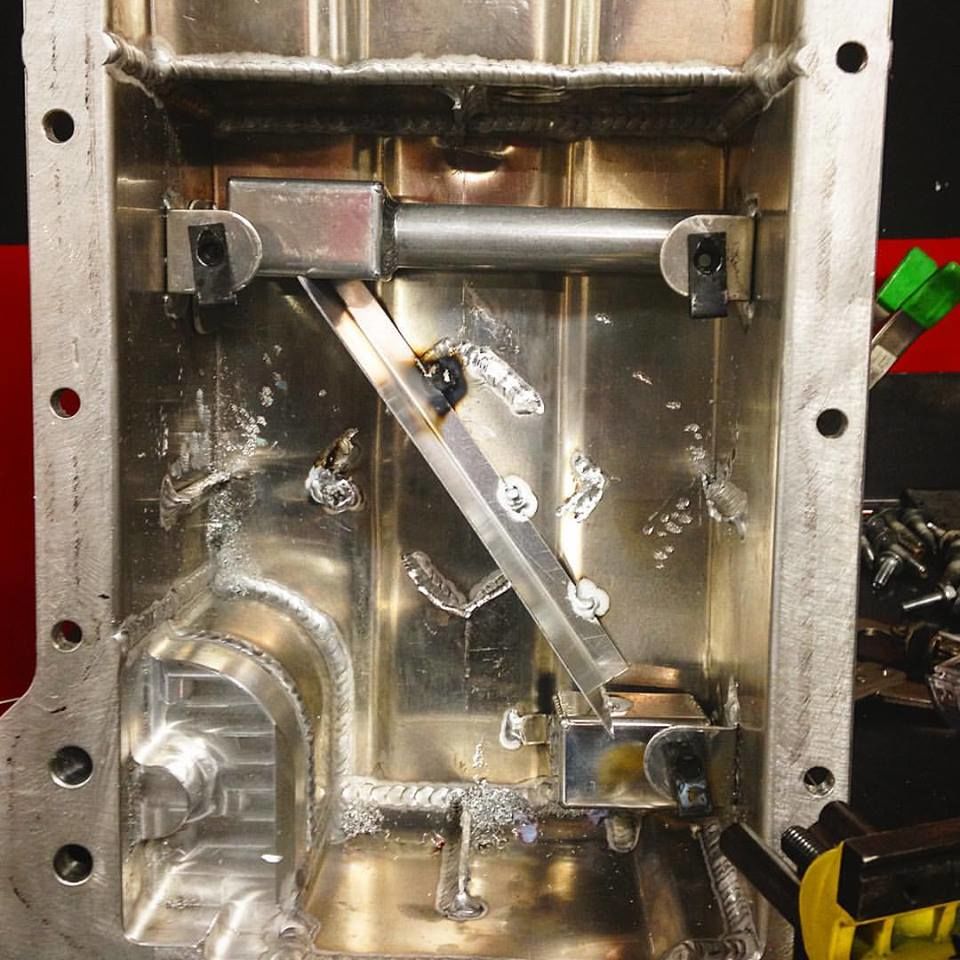

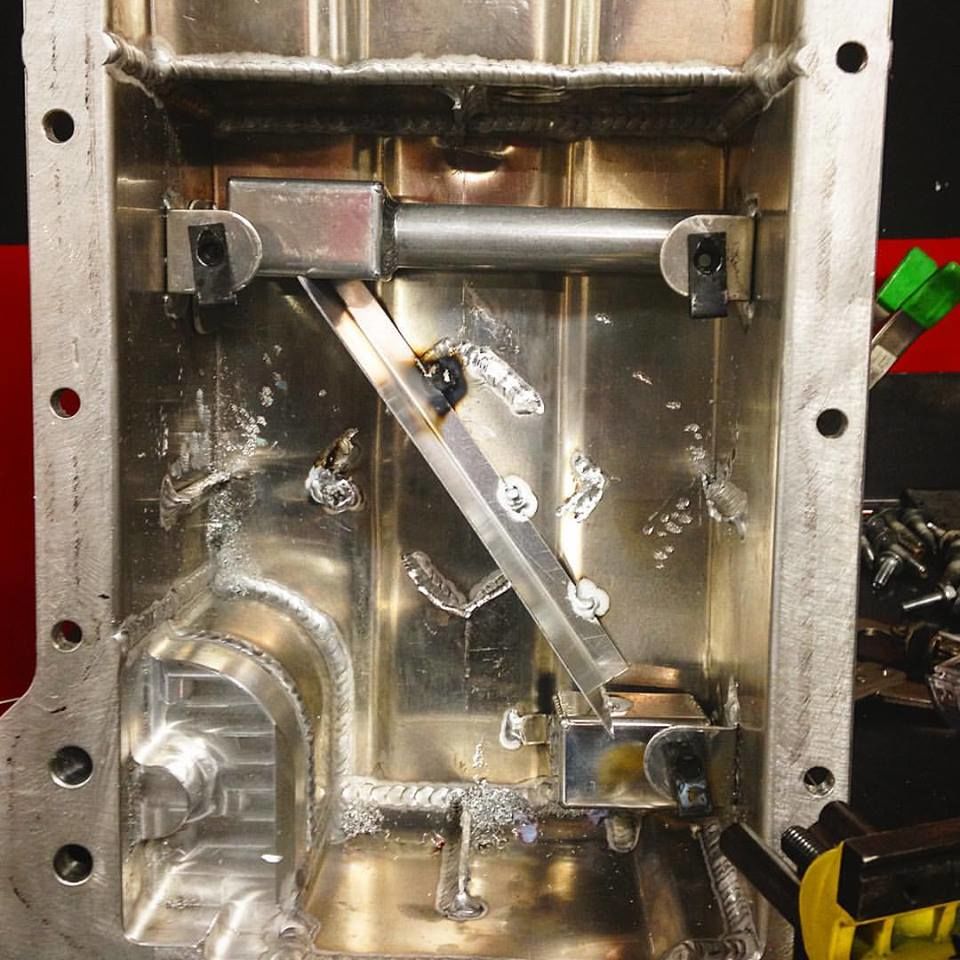

i've Been getting down on myself as the dry sup pan has been a nightmare. i don't have the ability to weld aluminum, so I've been relying on others and favors. well after taking too two different shops Vengeance Road Racing pulled threw last night.

so it's going to have two scavenge lines. one front left, one rear right. with a baffle that directs the flow to the front or the rear.

We are doing what is called a Stage 1 dry sump. what that is we are using the internal pump for pressure and relying on a external scavenge pump to fill the dry sump tank.this is the same process used by the PWC camaros and the Trans am 3 camaro teams. so it's tried and true to work. you really shouldn't need any more than this unless your looking to run more than 6500rpm. Anything over that and the stock pump spins too fast and isn't very happy. over that rpm an external under-driven pump is recommended.

so it's going to have two scavenge lines. one front left, one rear right. with a baffle that directs the flow to the front or the rear.

We are doing what is called a Stage 1 dry sump. what that is we are using the internal pump for pressure and relying on a external scavenge pump to fill the dry sump tank.this is the same process used by the PWC camaros and the Trans am 3 camaro teams. so it's tried and true to work. you really shouldn't need any more than this unless your looking to run more than 6500rpm. Anything over that and the stock pump spins too fast and isn't very happy. over that rpm an external under-driven pump is recommended.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#32

The main line goes threw a soft line and a bulkhead. Those are swivle ends, and can move slighly. The bulkhead has a hole threw the pan and secures with a nut and a alumanum/rubber washer. The idea is that ill tighten all the important joints first. Then wheezle the bulkhead threw the hole in the pan and tightnen the nut. In my mind it will be easy :P.

#34

sterted off with an idea of where i wanted to run it.

sterted off with an idea of where i wanted to run it.  i just started cutting and tacking.

i just started cutting and tacking.  ran out of header piper really quick so i had to make a summit run, and get some more 1.75" tube.

ran out of header piper really quick so i had to make a summit run, and get some more 1.75" tube.  end of sat, this is how it looked.

end of sat, this is how it looked.  next day i was feeling a down on progress. so thought about going to a demo Derby.

next day i was feeling a down on progress. so thought about going to a demo Derby.  but got back to work and kept cutting.

but got back to work and kept cutting.  i think overall the header runners are a good 3' long.

i think overall the header runners are a good 3' long.  up swept headers.mmmmmm i had to ditch my holley valve covers and go back to stock. i'll also need ASA plug wires to run around the headers.

up swept headers.mmmmmm i had to ditch my holley valve covers and go back to stock. i'll also need ASA plug wires to run around the headers.  finished up the Side pipes on both sides Monday night. it was a ton of work. good 3 day project.

finished up the Side pipes on both sides Monday night. it was a ton of work. good 3 day project.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#35

pedals are in. and plumbed. i still need to make a false floor for them.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

<br >

<br >