HPDE Fail- 240's engine build

#1

Thread Starter

Elite Member

iTrader: (2)

Joined: May 2007

Posts: 2,608

Total Cats: 16

From: Cromwell, Connecticut

So as some of you know, my poor little 1.8 didn't survive my first track day. It started making some ticking noise when warm... sounds like the classic Subaru piston slap. Most likely rings and/or wrist pins are fucked up.

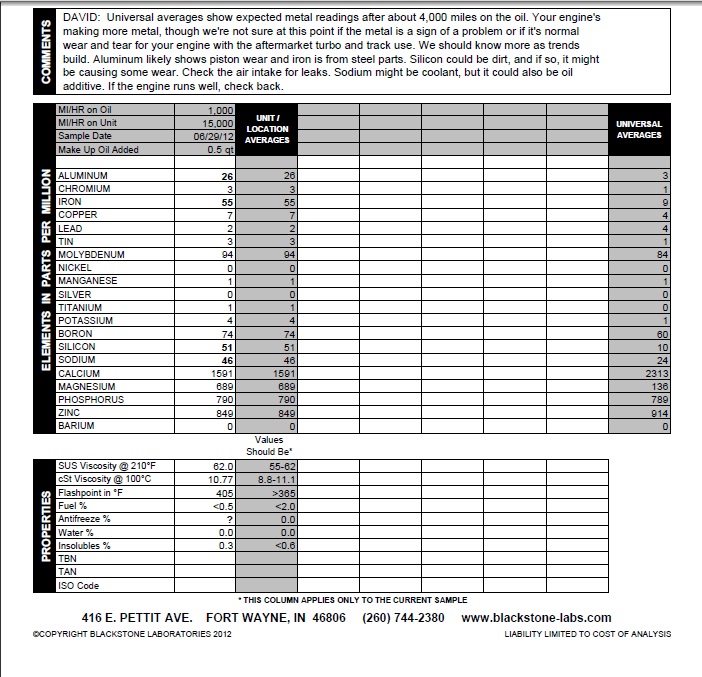

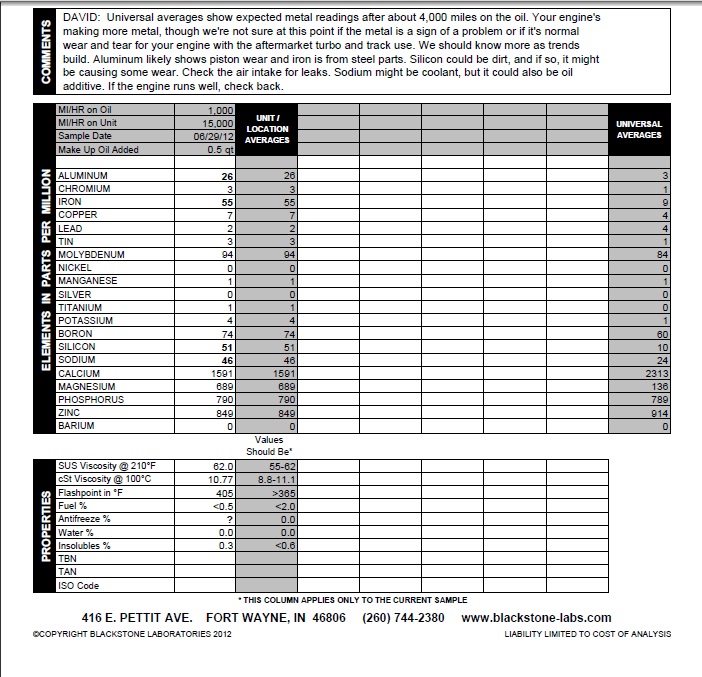

Just for ***** I got a blackstone lab report to maybe confirm what I thought before tearing into the motor. It showed high amounts of aluminum and iron...

So... Time to rebuild. Between finishing my paint project, buying xida CS's & TSE 11.75", I am broke . . . So I plan on only building the bottom end and "refreshing" the head with a valve job & new seals. A yr or 2 down the road Ill go VVT.

. . . So I plan on only building the bottom end and "refreshing" the head with a valve job & new seals. A yr or 2 down the road Ill go VVT.

I plan on:

-Supertech 9:1 84mm pistons

-M-tuned rods (already have them in the current engine. gotta check that they are still good)

- ACL Race Bearings

- ARP head & main studs

- Boundary Street/Strip highflow pump (shimmed)

- TSE Inconel turbo studs

- Fresh rebuild on the turbo, powder coating, etc.

So far I have most of the parts. My pistons came with no rings but emilio says they usually ship separate. I will be bringing the motor to Center Auto in Stratford, CT. They will be doing all the machine work including balancing the rotating assembly. They also are going to be assembling the short block so I know its right.

I pulled the motor today. My 10x15 unit is REALLY tight but it gets the job done.

PACKED

Just for ***** I got a blackstone lab report to maybe confirm what I thought before tearing into the motor. It showed high amounts of aluminum and iron...

So... Time to rebuild. Between finishing my paint project, buying xida CS's & TSE 11.75", I am broke

. . . So I plan on only building the bottom end and "refreshing" the head with a valve job & new seals. A yr or 2 down the road Ill go VVT.

. . . So I plan on only building the bottom end and "refreshing" the head with a valve job & new seals. A yr or 2 down the road Ill go VVT.I plan on:

-Supertech 9:1 84mm pistons

-M-tuned rods (already have them in the current engine. gotta check that they are still good)

- ACL Race Bearings

- ARP head & main studs

- Boundary Street/Strip highflow pump (shimmed)

- TSE Inconel turbo studs

- Fresh rebuild on the turbo, powder coating, etc.

So far I have most of the parts. My pistons came with no rings but emilio says they usually ship separate. I will be bringing the motor to Center Auto in Stratford, CT. They will be doing all the machine work including balancing the rotating assembly. They also are going to be assembling the short block so I know its right.

I pulled the motor today. My 10x15 unit is REALLY tight but it gets the job done.

PACKED

#5

Joined: Jun 2006

Posts: 29,085

Total Cats: 375

From: Republic of Dallas

If it makes you feel any better, I have that same sized garage space, a tire trailer, three extra sets of wheels and tires, two spare engines, two spare transmissions, two rear ends, a rack for bulk fluids, a hoist, trans jack, and a work table...and the green car. It sucks.

#6

If it makes you feel any better, I have that same sized garage space, a tire trailer, three extra sets of wheels and tires, two spare engines, two spare transmissions, two rear ends, a rack for bulk fluids, a hoist, trans jack, and a work table...and the green car. It sucks.

#9

Thread Starter

Elite Member

iTrader: (2)

Joined: May 2007

Posts: 2,608

Total Cats: 16

From: Cromwell, Connecticut

They technically don't... but I have never run into issues. usually the management is pretty cool. The one that I have during the winter/spring in my parents town is awesome. 10x30 and they are really cool about car stuff. They let me run a 100ft extension cord and grab power.

I will be ditching emissions ---- after I pass. I am a yr late so thats mission #1 when the motor is running. My reg. expires jan 2013 so I NEED to do emissions this fall.

I will be ditching emissions ---- after I pass. I am a yr late so thats mission #1 when the motor is running. My reg. expires jan 2013 so I NEED to do emissions this fall.

#11

Thread Starter

Elite Member

iTrader: (2)

Joined: May 2007

Posts: 2,608

Total Cats: 16

From: Cromwell, Connecticut

I am not assembling the short block. I assembled the last one and it all went ok but with some high dollar parts & machine work going into this one I think $200 for professional assembly is cheap insurance.

#12

Thread Starter

Elite Member

iTrader: (2)

Joined: May 2007

Posts: 2,608

Total Cats: 16

From: Cromwell, Connecticut

HOLY WAR ZONE!!!!!

Engine goes to the machine shop Thursday!! All I can see from having the head off is some slight detonation on cylinder 1, and some slight markings on cylinder 4 wall. Its still very smooth tho. I think the det was there last time I had the head off, so I am still guessing cylinder 4 rings or wrist pin is shot.

Engine goes to the machine shop Thursday!! All I can see from having the head off is some slight detonation on cylinder 1, and some slight markings on cylinder 4 wall. Its still very smooth tho. I think the det was there last time I had the head off, so I am still guessing cylinder 4 rings or wrist pin is shot.

#15

Thread Starter

Elite Member

iTrader: (2)

Joined: May 2007

Posts: 2,608

Total Cats: 16

From: Cromwell, Connecticut

UPDATES UPDATES UPDATES

Evan (adriver1990) was right... rod bearings. I trashed all 4. Luckily I stopped early enough where the crank and rods are still okay and I can still use standard bearing sizes...

I swung by the shop before waterfest to see the damage:

Hopefully I will get the engine back in another week or so. I am still missing the oil pump. In the mean time I am rebuilding the turbo, powerdercoating parts, and upgrading to TSE INCONEL M10's

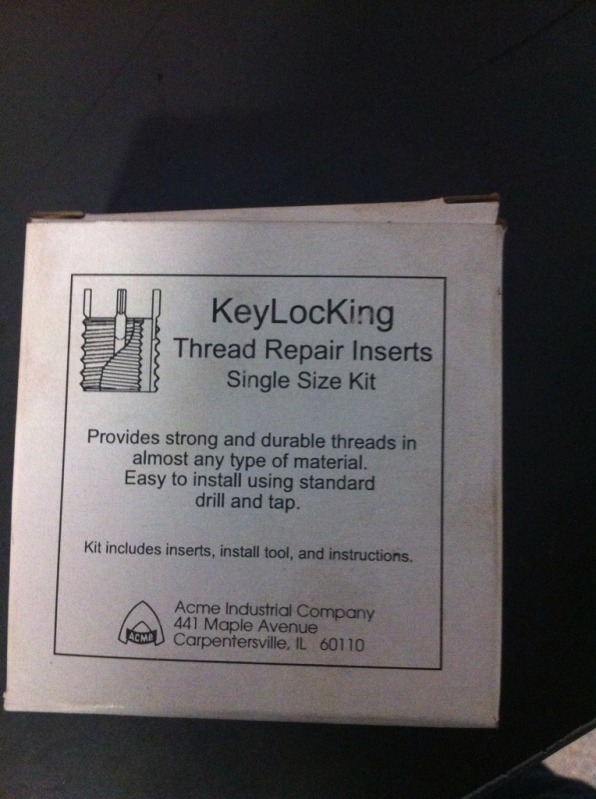

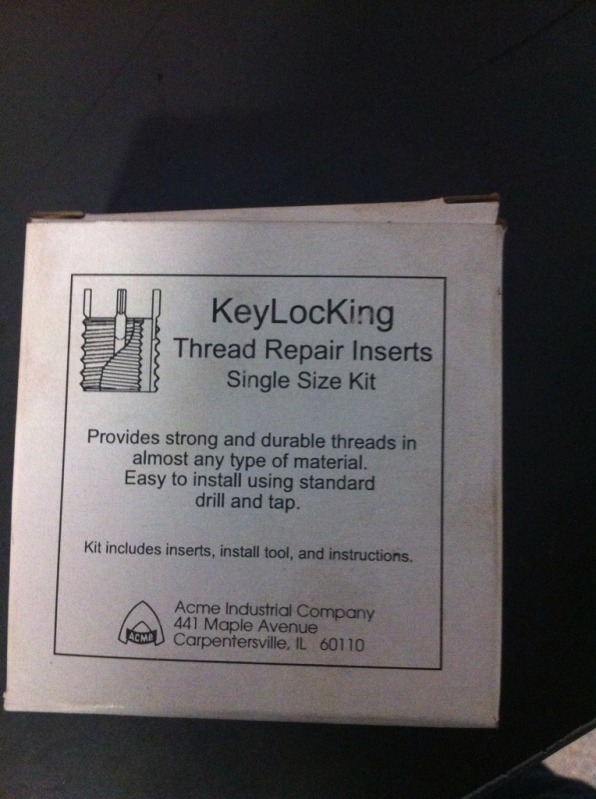

I F'ed up my manifold machining out a broken M8. I lost the center and ended up oblonging the hole. My solution was to use keyed threaded inserts because they cant back out. Only issue is I plunged a bit too deep and broke thru into the inside of the manifold. I am hoping that the exhaust gas wont leak thru the threads...

I think I am going to finish rebuilding the turbo tomorrow and then use the eastwood hotcoat powdercoating gun to do my valve cover later this week!

Oh my friend also welded up some IC pipes for me. I haven't picked them up yet.

Evan (adriver1990) was right... rod bearings. I trashed all 4. Luckily I stopped early enough where the crank and rods are still okay and I can still use standard bearing sizes...

I swung by the shop before waterfest to see the damage:

Hopefully I will get the engine back in another week or so. I am still missing the oil pump. In the mean time I am rebuilding the turbo, powerdercoating parts, and upgrading to TSE INCONEL M10's

I F'ed up my manifold machining out a broken M8. I lost the center and ended up oblonging the hole. My solution was to use keyed threaded inserts because they cant back out. Only issue is I plunged a bit too deep and broke thru into the inside of the manifold. I am hoping that the exhaust gas wont leak thru the threads...

I think I am going to finish rebuilding the turbo tomorrow and then use the eastwood hotcoat powdercoating gun to do my valve cover later this week!

Oh my friend also welded up some IC pipes for me. I haven't picked them up yet.

#18

Thread Starter

Elite Member

iTrader: (2)

Joined: May 2007

Posts: 2,608

Total Cats: 16

From: Cromwell, Connecticut

Finally picked up the motor...

Also cleaned all 16 of my HLA's. Took ENTIRELY too much time...but they are all squeeky clean and feel really smooth. I wish I still worked at The Lee Co, I would have slapped them in the Branson Ultrasonic cleaner. I did loose 2 springs so I grabbed a spare HLA from a friend and will steal the parts from that.

I will hopefully get a chance to start assembly soon.

Also cleaned all 16 of my HLA's. Took ENTIRELY too much time...but they are all squeeky clean and feel really smooth. I wish I still worked at The Lee Co, I would have slapped them in the Branson Ultrasonic cleaner. I did loose 2 springs so I grabbed a spare HLA from a friend and will steal the parts from that.

I will hopefully get a chance to start assembly soon.

#19

Thread Starter

Elite Member

iTrader: (2)

Joined: May 2007

Posts: 2,608

Total Cats: 16

From: Cromwell, Connecticut

Almost ready for powerdercoat. I'll be using the Eastwood powdercoating gun again. I am tempted to put AN fittings in, but for now i think I am going to keep the stock PCV & ghetto mini filter. I will do a catch can setup in the spring.