Goatse tries to boost and probably fails numerous times

#1

Hey miataturbo.net, starting off here with a little introduction of myself and my miata history. I funded myself through the past season of racing 100cc air-cooled race karts, and sad to say the karts we race are much much faster than the miata, as much as everyone likes making the comparison. :P I'm very young, and two years ago I purchased my first car and first miata at sixteen years old for 800 dollars. I've had a blast driving it and learning how to do basic maintenance work, been helping out a few friends with simple stuff like pulling the engine and transmission to do the clutch, water pump, timing belt, just trying to learn as much as I can.

Aforementioned blue turd:

I've been toying around with the idea of turbocharging my car, but it didn't seem very feasible as I have to have the car running every monday to get to class. A few months ago I ended up picking up a clean title rolling 91, with no engine or transmission. This put me a little closer towards my goal, as I now I have something to work on while I daily-drive my smurf, I still needed a powerplant.

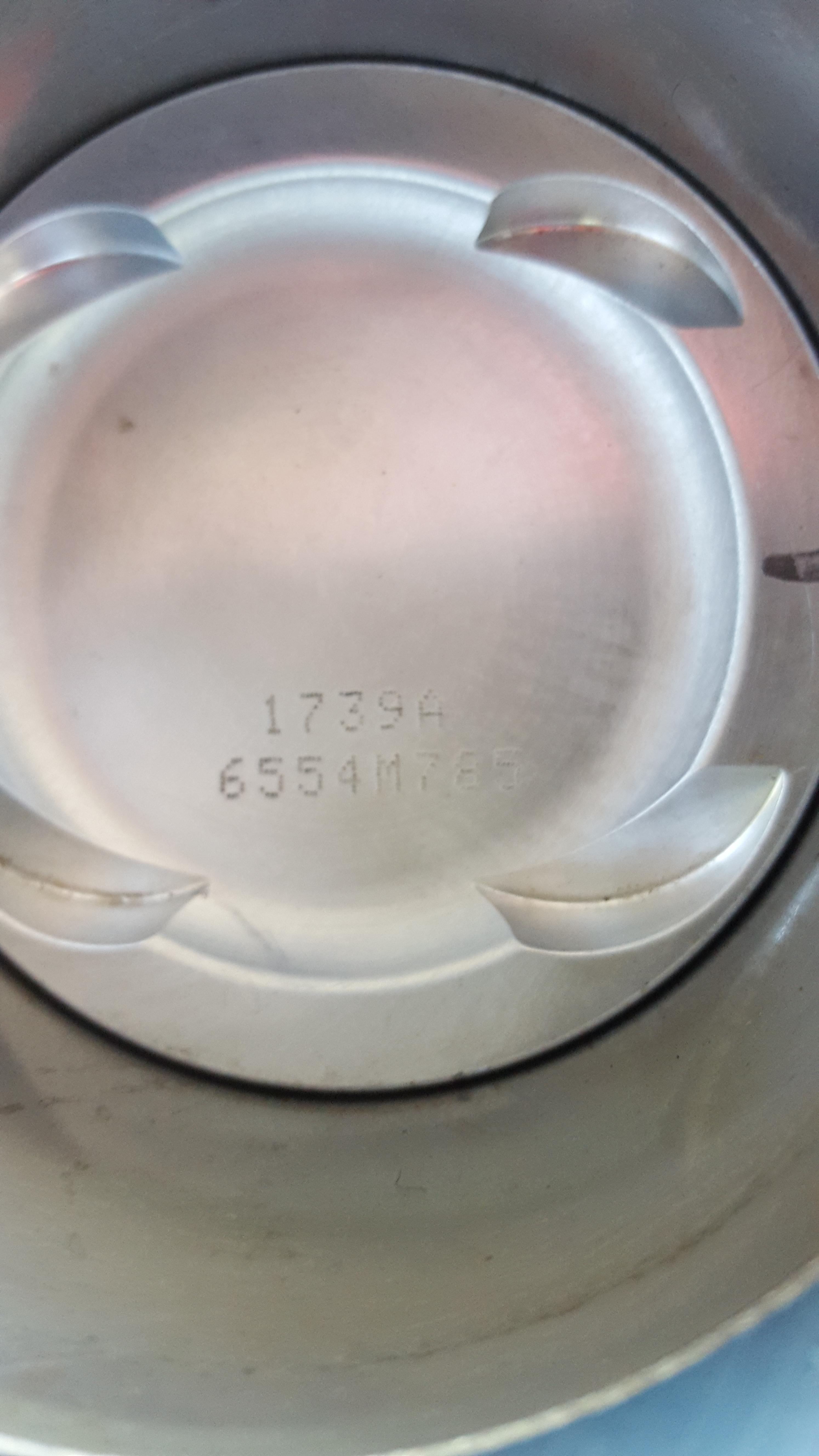

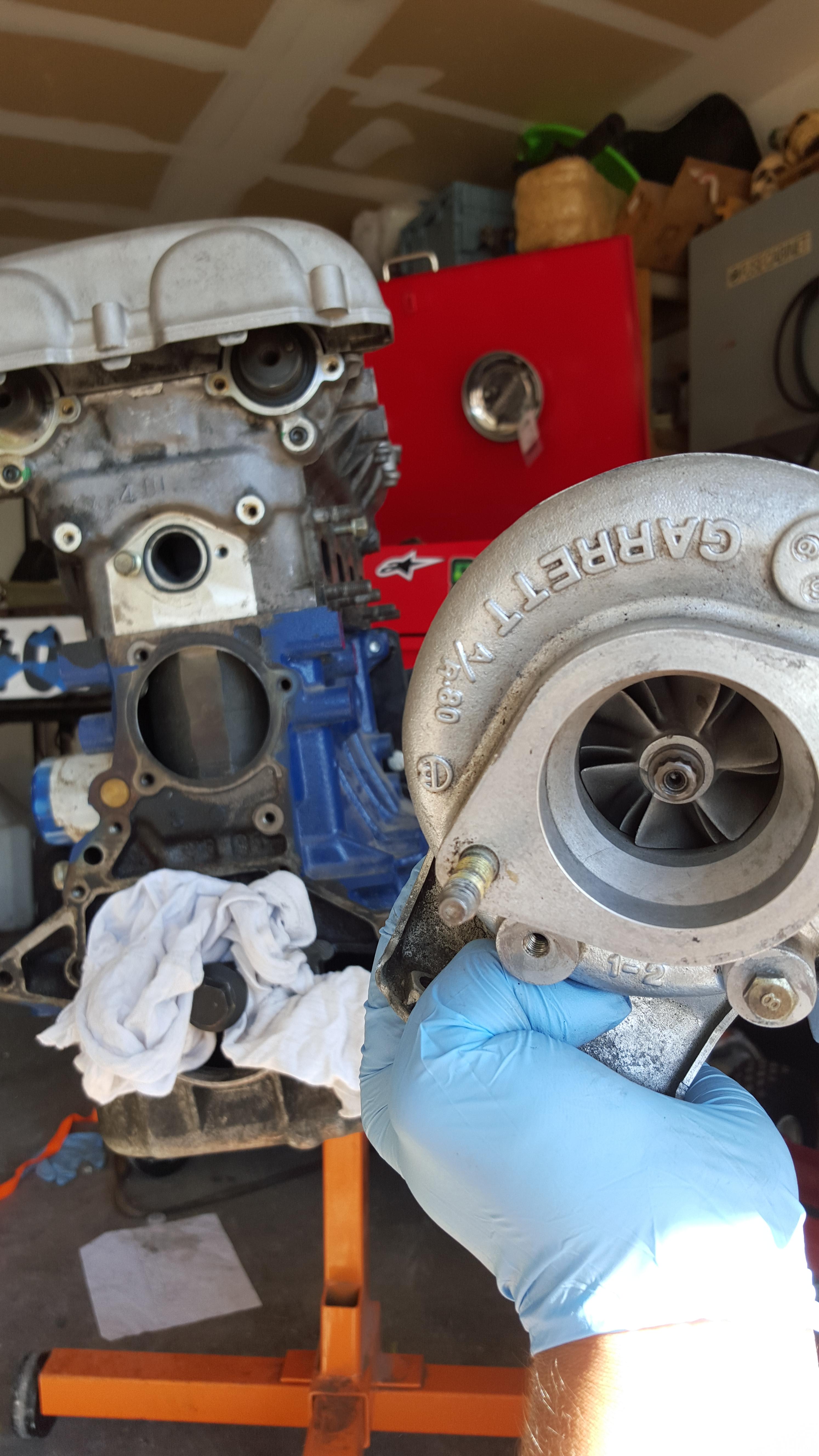

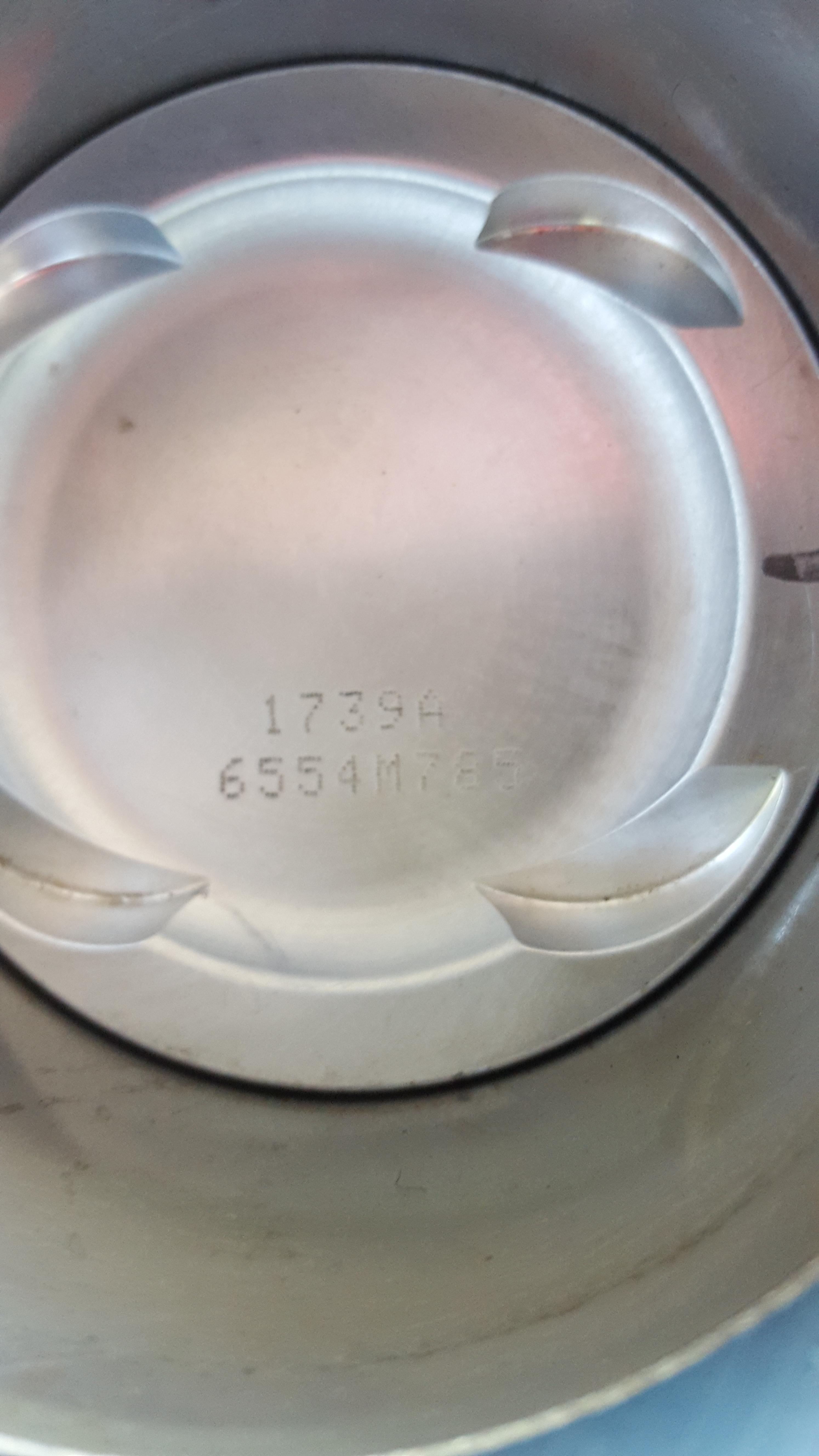

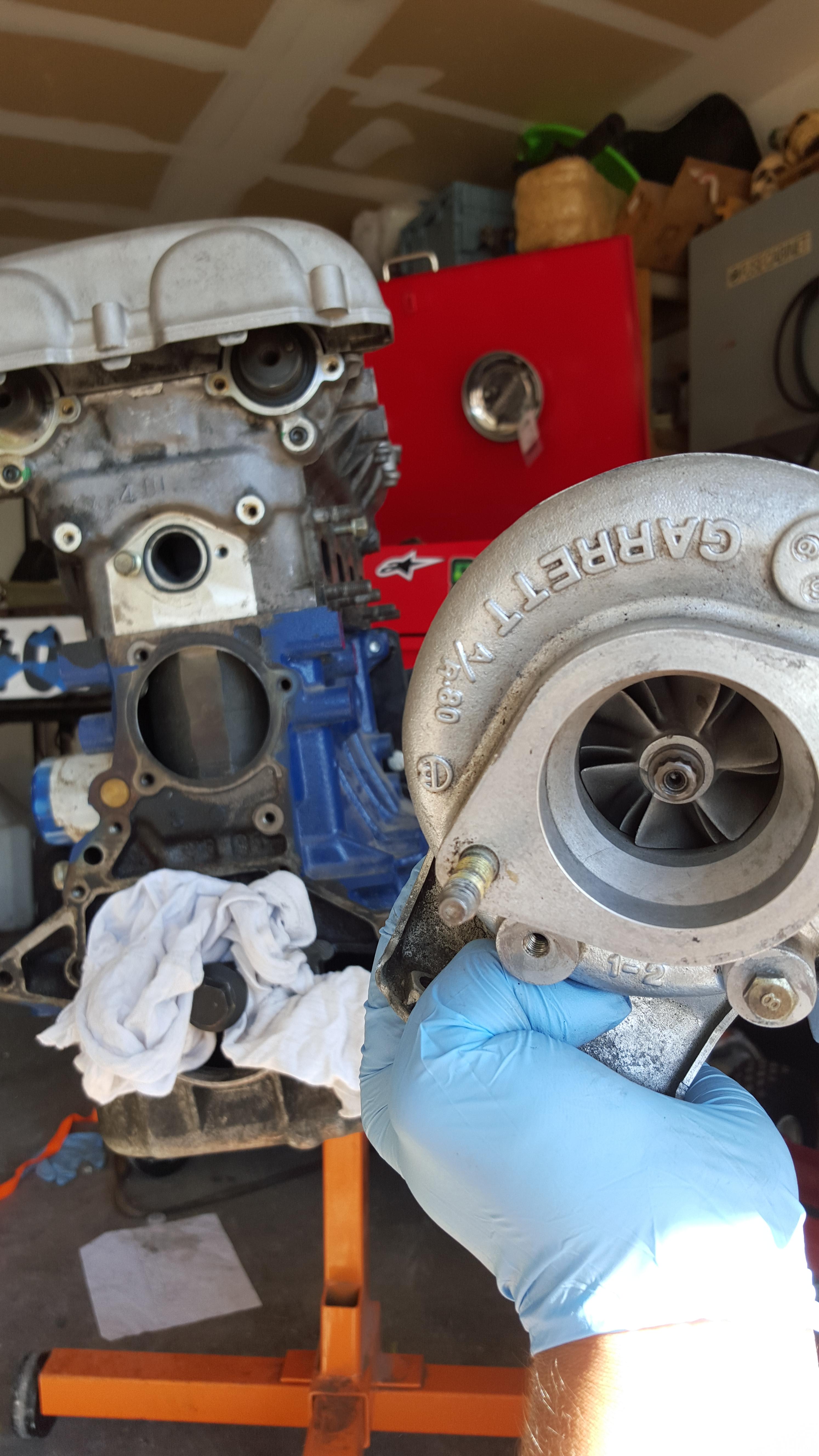

Enter this 1.6l engine I acquired yesterday for $250 dollars, from what I was told and the parts boxes that came with it, the short block was machined and assembled at a local machine shop with Wiseco turbo pistons and ebay forged H rods. I have no experience with 4 stroke engines whatsoever, so I imagine this is going to be a learning experience for me. Time to keep my head down and UTFSE, more to come. Thanks all!

Just gotta get this thing onto that thing! Can't be too difficult. Said no one ever.

Aforementioned blue turd:

I've been toying around with the idea of turbocharging my car, but it didn't seem very feasible as I have to have the car running every monday to get to class. A few months ago I ended up picking up a clean title rolling 91, with no engine or transmission. This put me a little closer towards my goal, as I now I have something to work on while I daily-drive my smurf, I still needed a powerplant.

Enter this 1.6l engine I acquired yesterday for $250 dollars, from what I was told and the parts boxes that came with it, the short block was machined and assembled at a local machine shop with Wiseco turbo pistons and ebay forged H rods. I have no experience with 4 stroke engines whatsoever, so I imagine this is going to be a learning experience for me. Time to keep my head down and UTFSE, more to come. Thanks all!

Just gotta get this thing onto that thing! Can't be too difficult. Said no one ever.

#2

Decided to migrate my images onto imgur as well as update information as I'm getting a lot of support on Reddit.

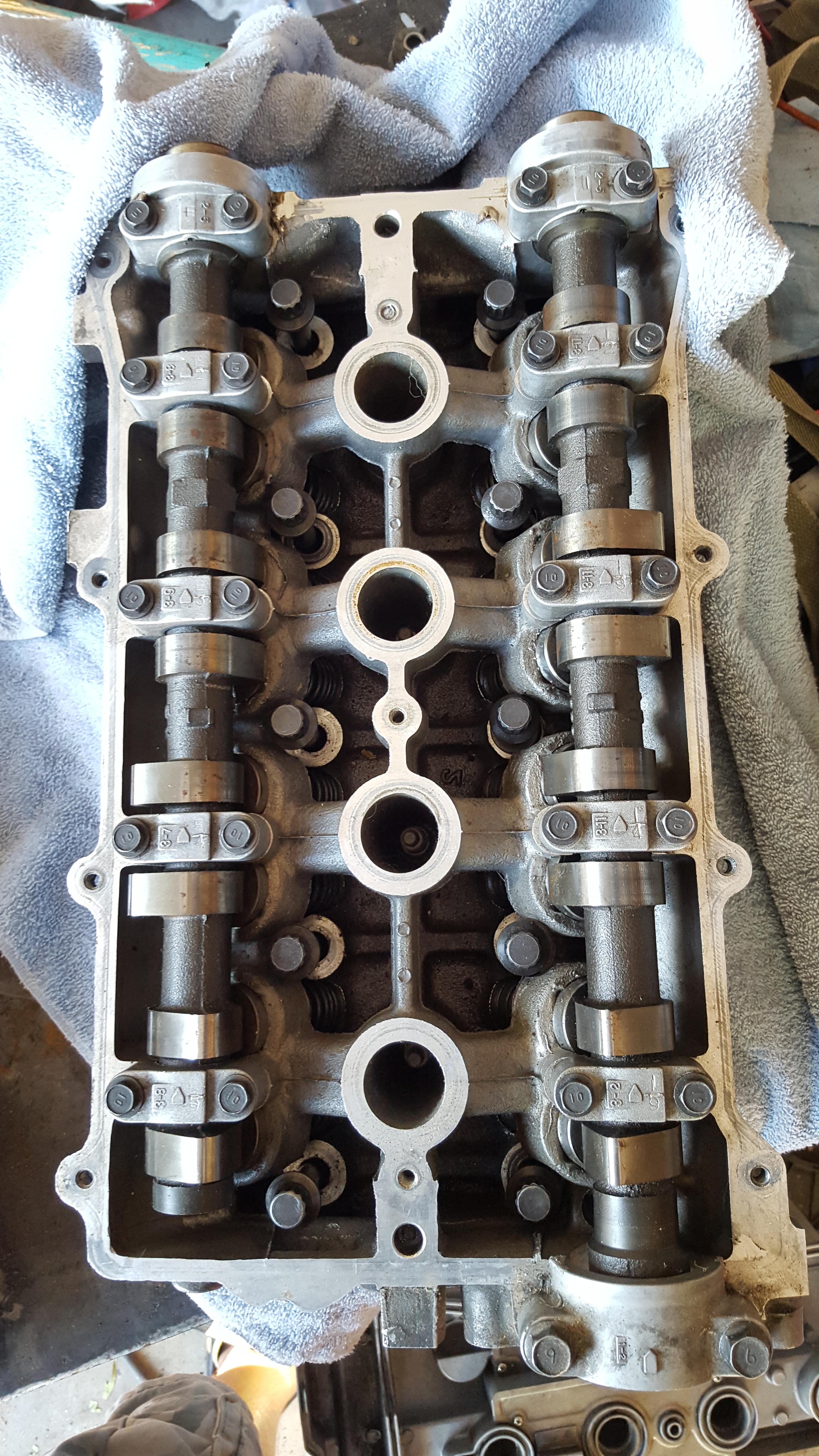

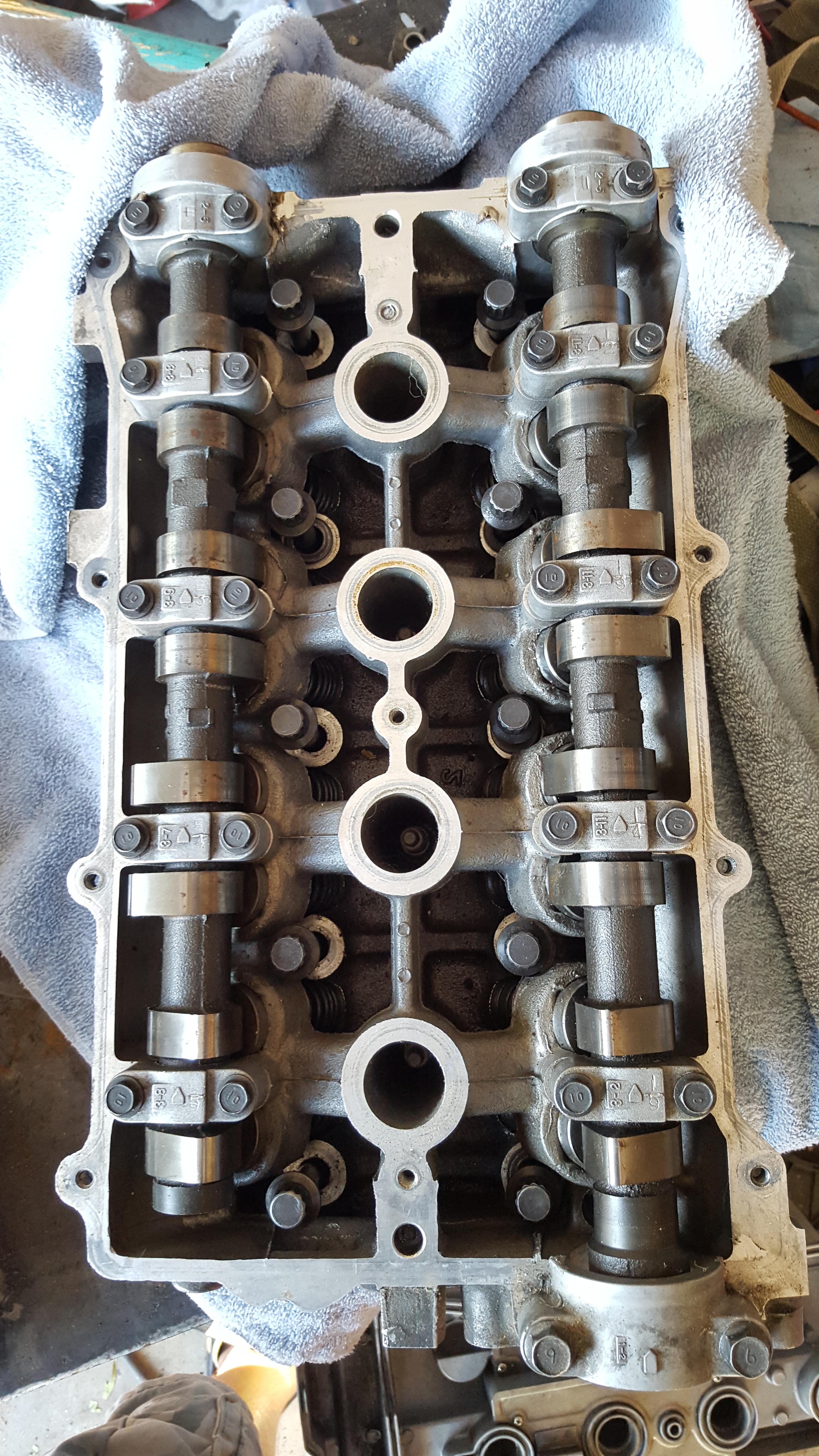

Started tearing down the head to clean it and the HLAs.

Miata 1.6 Head Tear Down Part #1 - Album on Imgur

Started tearing down the lower end to find out that the #2 bearing is shot, wonder if it could be from turning the engine over dry.

Imgur: The most awesome images on the Internet

Started tearing down the head to clean it and the HLAs.

Miata 1.6 Head Tear Down Part #1 - Album on Imgur

Started tearing down the lower end to find out that the #2 bearing is shot, wonder if it could be from turning the engine over dry.

Imgur: The most awesome images on the Internet

#5

Swap to a 1.8 rear diff first. Then do other things. 1.6 diffs fail at stock power.

The 1.6 and t25 turbo you have will be fine for you. It will do everything you need to do for the street just fine. If you didn't already have a forged 1.6 sitting there I would agree with Monk. You will be able to more than double the stock horsepower pretty easily. But know that double the stock horsepower will still only put you even with a new v6 Camry in acceleration (14.2 ET, which used to be Corvette times in the early nineties 14.1 ET, lol).

The 1.6 and t25 turbo you have will be fine for you. It will do everything you need to do for the street just fine. If you didn't already have a forged 1.6 sitting there I would agree with Monk. You will be able to more than double the stock horsepower pretty easily. But know that double the stock horsepower will still only put you even with a new v6 Camry in acceleration (14.2 ET, which used to be Corvette times in the early nineties 14.1 ET, lol).

#9

Sorry for the lack of progress guys, was in the hospital, THEN got in an accident with the blue miata. I figured it was definitely not worth it to go spend a few hundred on another engine when the only thing that needed to be done was have the rod journals polished and buy another ~30 dollar set of bearings... Especially since I have all these nice parts. Is there that significant of a difference that it would be worth taking a loss on these fancy parts never used to go out and a buy a used 1.8 and run it stock?

Brought my other miata home.

The scratches on the journals.

Uhh.. Not sure if I've been doing this right. Might need to find someone who actually knows what they're doing.

Bought some things.

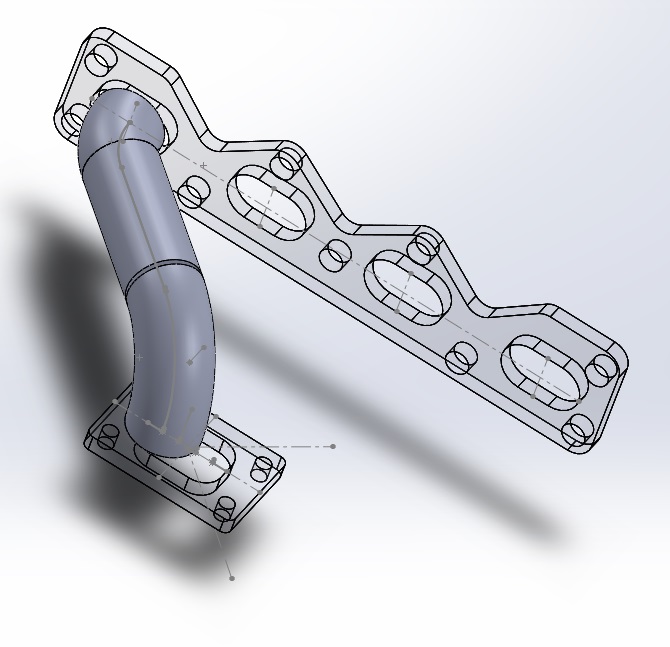

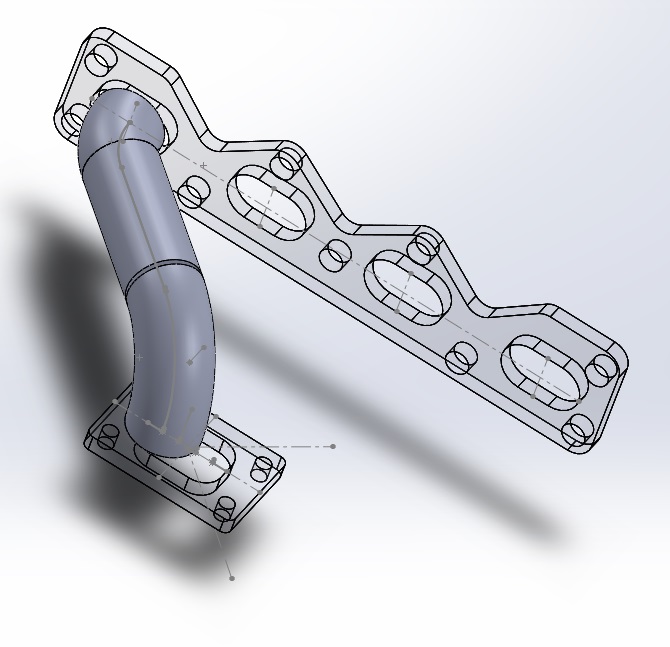

Started working on a thing. Is anyone here proficient with solidworks who'd be willing to answer a few questions?

Brought my other miata home.

The scratches on the journals.

Uhh.. Not sure if I've been doing this right. Might need to find someone who actually knows what they're doing.

Bought some things.

Started working on a thing. Is anyone here proficient with solidworks who'd be willing to answer a few questions?

#15

Thanks 240! So I've been trying to teach myself solidworks to help pre-plan some of my attempts at fabrication. Been learning a little lathework and trying to learn how to tig.

In the last picture you can see my attempts so far at modelling up my manifold in 1 1/4 Sch 40. (All design credit to mr. absurdflow, your work is wonderful.) and I've decided to go with prebent 'weld elbows'. A lot of the bent sections seem to be designed from cut down sections of an already prebent section of tubing at a constant radius, say, I want to make a much more slight bend where the runner is to go and I cut down a 90 degree weld elbow at 3" radius to whatever length necessary to get the desired angle.

In solidworks I've been using fillets to attempt to model the radii, but I've run into the problem that I can not create a radius bigger than the length of the two segments that create an angle. My question is, if I have an angle comprised of a 1" leg and another leg, how would I model a 3" radius into such a short section?

In the last picture you can see my attempts so far at modelling up my manifold in 1 1/4 Sch 40. (All design credit to mr. absurdflow, your work is wonderful.) and I've decided to go with prebent 'weld elbows'. A lot of the bent sections seem to be designed from cut down sections of an already prebent section of tubing at a constant radius, say, I want to make a much more slight bend where the runner is to go and I cut down a 90 degree weld elbow at 3" radius to whatever length necessary to get the desired angle.

In solidworks I've been using fillets to attempt to model the radii, but I've run into the problem that I can not create a radius bigger than the length of the two segments that create an angle. My question is, if I have an angle comprised of a 1" leg and another leg, how would I model a 3" radius into such a short section?

#16

Aidanj, is there a significant difference in the 'limit of potential power' (is that a thing?) between the 1.6l engines and the 1.8? I understand with the later year engines you have options for much better flowing heads, correct? With the large nose crank are the still serious reliability issues between these engines and the later year 1.8s? Thank you.

#19

The 1.8 and 1.6 have the same basic limitations in terms of block weight (they're both iron), rod ratio, NVH, oil pump gears, cam profiles, hydraulic lifter limitations, head flow. The difference is that a 1.8L will spin up a turbo of a given size more quickly. If you consider the 99+ heads, the 1.8 can also rev higher and make more power at higher RPM as well.

So basically the 1.8 will make more power off boost, make more power on boost and it will reach boost sooner. It's literally better in every way. There is no tradeoff except in terms of the labor required to put it in your engine bay. If you're doing a rebuild on a 1.6, you need to remove the engine anyway, so it's basically a free upgrade to build the 1.8L and put that back in the engine bay..

So basically the 1.8 will make more power off boost, make more power on boost and it will reach boost sooner. It's literally better in every way. There is no tradeoff except in terms of the labor required to put it in your engine bay. If you're doing a rebuild on a 1.6, you need to remove the engine anyway, so it's basically a free upgrade to build the 1.8L and put that back in the engine bay..

#20

1.8 is not free.

You need a block, then pistons, then an oil pan, pickup and all that. You could use your 1.6 cas on a 1.8, but the crank sensor's better, alternator, crank pulley, intake manifold, reroute spacers and outlets, valve cover, timing covers, more more more...

Everyone says 1.8 is free, but it's not. All this **** costs money, probably more than you've spent in total on the car already.

**** it, 1krpm in spool lost isn't that bad.

If I were to attempt designing a manifold in solidworks from weld-el's I'd model the bends I'd be using, maybe even download them from mcmaster or something then throw them all together in an assembly, making cuts on the parts as necessary.

A basic weld-el would best be done as a swept sketch, something like this.

You need a block, then pistons, then an oil pan, pickup and all that. You could use your 1.6 cas on a 1.8, but the crank sensor's better, alternator, crank pulley, intake manifold, reroute spacers and outlets, valve cover, timing covers, more more more...

Everyone says 1.8 is free, but it's not. All this **** costs money, probably more than you've spent in total on the car already.

**** it, 1krpm in spool lost isn't that bad.

If I were to attempt designing a manifold in solidworks from weld-el's I'd model the bends I'd be using, maybe even download them from mcmaster or something then throw them all together in an assembly, making cuts on the parts as necessary.

A basic weld-el would best be done as a swept sketch, something like this.