Changing some stufff 2004 MSM

#9

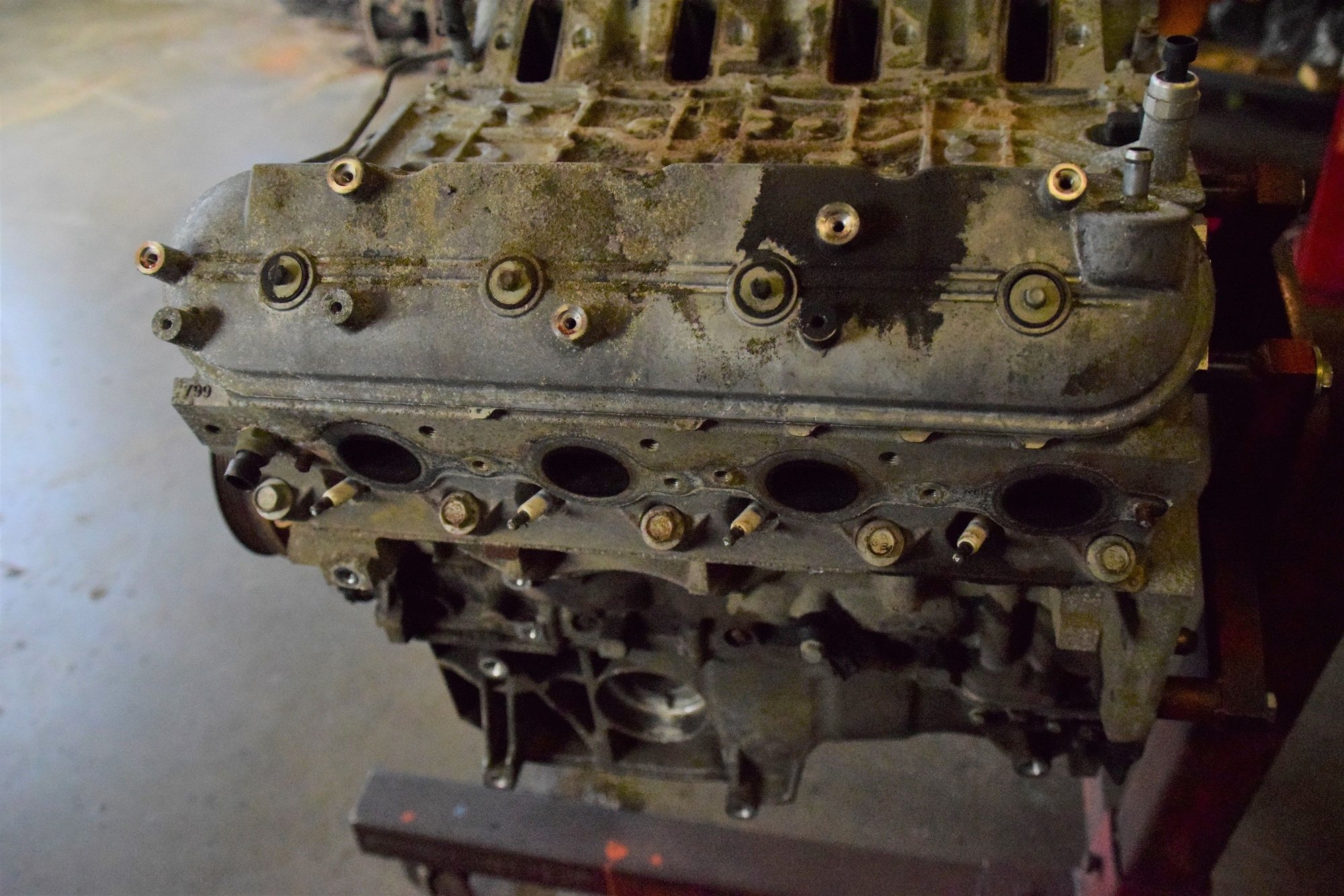

I still was looking for Miata engine that would solve my problem. I broke a factory connecting rod. The rest of the engine internals were junk. I started to add up the price to get back to where I began.I checked for a good engine builder in my area. I didn't like what I got for answers and dollar signs.

Last edited by overthetop; 11-11-2021 at 01:50 PM. Reason: Typo

#16

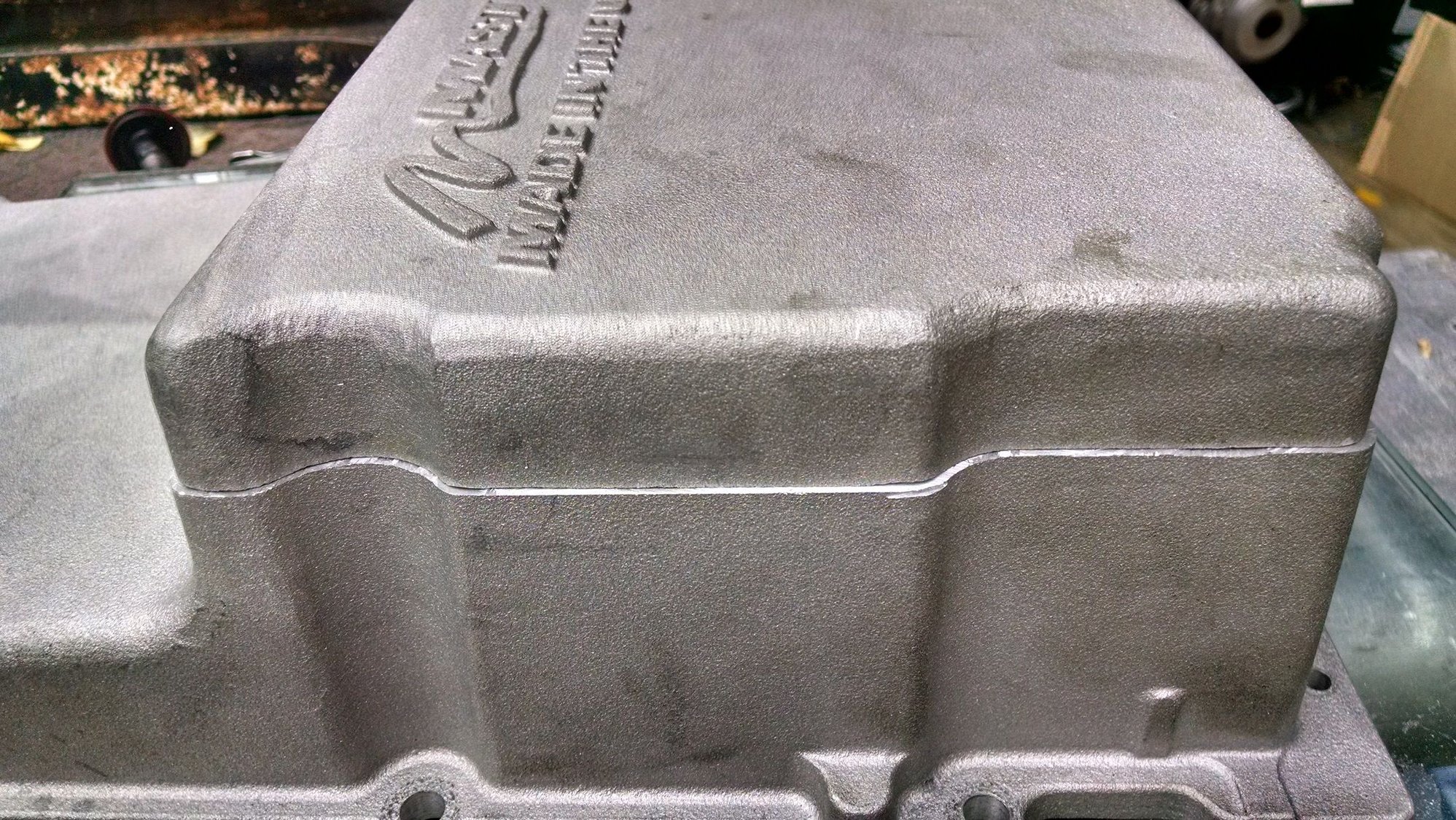

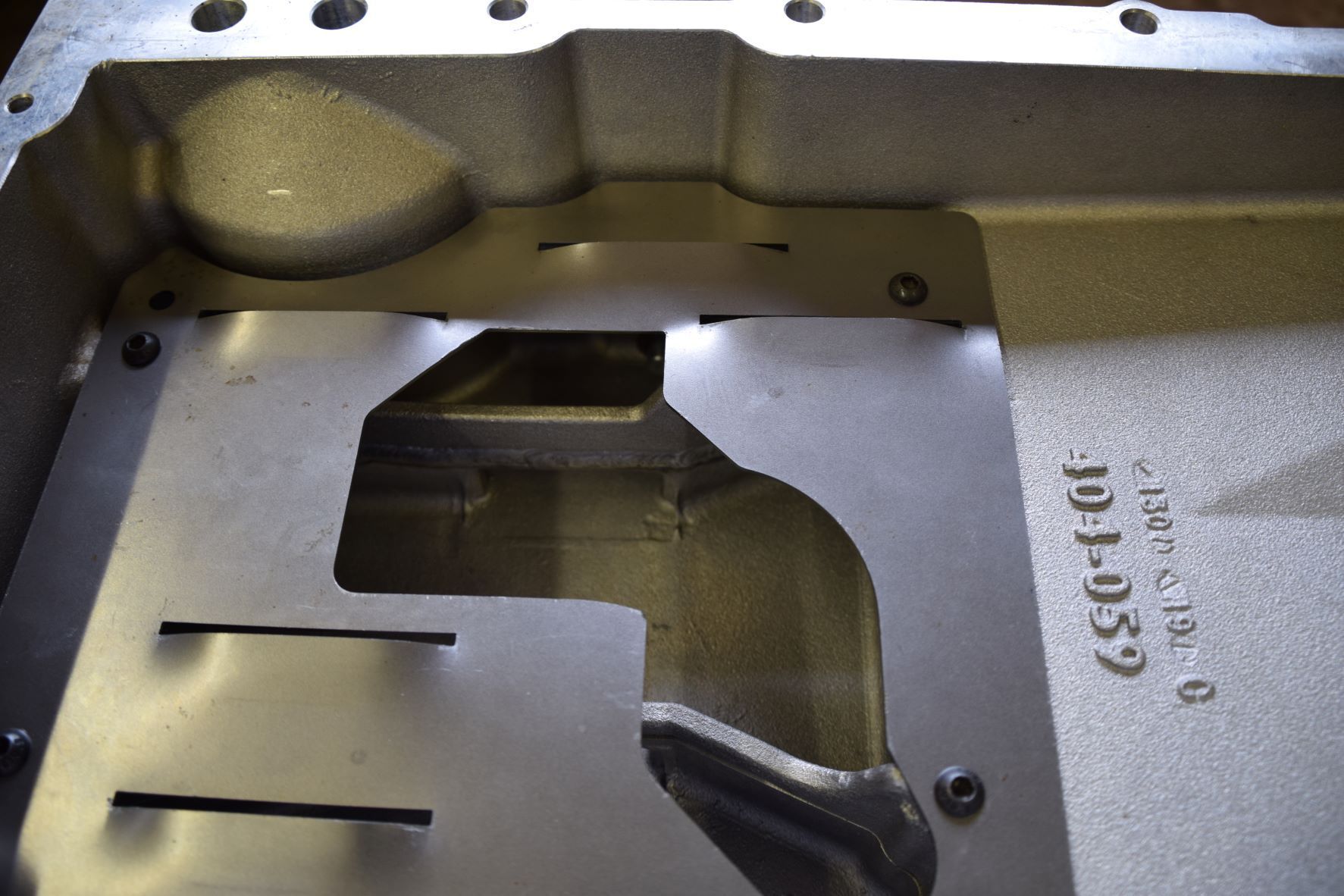

The Mast oil pan is 5 3/4 deep. I don't want it hanging below the frame.

Trial fitting the engine. The oil pan is too low.

The photo very blurry. This plus the kerfs of the two cuts equals one inch.

The cuts are finished. The welding is next.

The inside is also welded.

After the cuts and welding were completed.

#19

All the braces removed from the trans tunnel.

First, widening the tunnel for the bellhousing and then closing it back in a little for the accelerator to clear, lens cap for clearance from the gas pedal to the tunnel.

There were a surprising amount of small adjustment to be made with the tunnel so, I just ended up adding metal where is needed to go and then I reattached the tunnel braces.

#20

Getting the bellhousing to tunnel measurements. The Quicktime spun housing must have been different than the factory GM aluminum measurements, because the width was less than Flyin Miata directions listed. After following their recommendation, I had to narrow the opening slightly. Als, if I had known, I would have given myself slightly more height to allow for room for driveshaft angularity later.