2010 Grassroots Challenge Turbo Jeep Cherokee

#1

Thread Starter

Junior Member

iTrader: (9)

Joined: Apr 2007

Posts: 237

Total Cats: 0

From: Hanover, MA

Just wanted to share a build thread for our 2010 Grassroots Challenge Turbo Jeep Cherokee since my turbo and MegaSquirt knowledge came from this site. I mainly copy and pasted my teammate's tread from GRM but I should be able to answer any additional questions.

PART 1 We started the project with a difficult search of finding a two door, two wheel drive Jeep Cherokee. As it turns out one was recently brought up to New Hampshire from Mississippi for us! Talked the dealer down to $600. Let’s face it; no one in New England wants a 2WD Jeep. Good news for us.

Windshield cracked no title, 243k miles, chunky brown coolant, but running great, no real rust and fairly straight body. The only bad part is that we couldn’t find a manual transmission XJ. The automatic transmission (AW4) is bulletproof though so it isn’t all bad news.

We started the build with finding our starting weight. Not terribly heavy at all, only 2,865 lbs, and began removing the roof rack, rear seats and other unnecessary items like a/c and heater accessories, wiper motors (front and rear) and radio and speakers. We also gutted the hood and installed pins. Final racing weight in Gainesville was a very respectable 2,677 lbs.

Second step was to find a suitable rear axle. Since they are plentiful, strong, come with disk brakes, limited slip, and have better gearing (3.73 vs. 3.55) the Ford 8.8 out of an Explorer was the perfect solution. $100 for a nasty looking one at a junk yard was the easy part. We then cut the spring perches and re-welded them at the proper width for a Jeep Cherokee but flipped them to the bottom so we could convert to a spring-under layout achieving the rear suspension drop of about 4.5". Used U-Bolts attached the stock Jeep leaf springs to the Ford Axle. A $25 adapter from Spicer made the job of attaching the Ford axle to the stock Jeep drive shaft a breeze.

To increase spring rate we used a second pair of junk sagged stock Cherokee springs and doubled up most of the leaves with the original pack. It gave us more spring rate without increasing ride height.

Finding shocks for a lowered Jeep Cherokee proved to be difficult but after a lot of research on shock lengths and specs, craigslist got us a pair of new Rancho 5000 shocks for a Ford F150 for the front and a pair of used Bilstein shocks off a Toyota Tacoma TRD in the rear. They are both compressed a lot but should do the trick. We may have to look into ways to get more travel out of the system if its purpose expands from just autocross as they would bottom out too quickly for rally-cross duty.

The front axle was much more involved. Since the solid tube front axle could hit the oil pan under full compression we decided to cut and notch it. Having had lifted jeeps in the past we knew the big problems that can arise from changing the angles of the control arms so we needed to address that. The upper and lower control arm brackets on the axle were shortened and lengthened respectively to compensate for the drop in the front. Additionally we made a drop bracket off the axle to use a stock length track rod that still centered the axle after all the changes.

Since offset front ball joints are way to rich for the budget and we were cutting the front axle anyway we decided to notch and bend the front axle for additional camber. After researching more about the front axle modifications the Archer brothers used successfully racing the Jeep Comanche in the SCCA Truck Challenge series we found that they actually bent the front axle. Since we don’t have the facilities to accurately bend it whole, we cut a pie out of the middle leaving a small portion at the bottom intact and stood on it until we ultimately achieved -2.5 degrees static camber on each side.

A great deal on poly front control arm bushings firmed up the axle control and a few sections of steel plate were welded onto the stock control arms to box them in for strength. The new axle modifications clear the oil pan with room to spare and the control arms retain their stock angles.

The driveline was firmed up with poly motor mounts found on eBay for $0.99! They were for a Jeep Wrangler (TJ) so they had to be cut approximately 1” to fit an XJ. We couldn’t find a steal like that on a transmission mount so we injected some polyurethane into the voids in the stock sagged rubber mount and let it cure. What a difference!

Used crusty Addco anti-sway bars were taken off a parted out Jeep and installed front and rear. They’re 1-1/8" front and 7/8" rear. The rear links are poly bushings with washers and a long bolt and we had to fabricate and weld a mounting location onto the rear axle. The stock front links were cut shorter and rewelded to fit the much lower suspension. The combination of cut springs, stiffer shocks and sway bars results in a very stiff vehicle.

PART 1 We started the project with a difficult search of finding a two door, two wheel drive Jeep Cherokee. As it turns out one was recently brought up to New Hampshire from Mississippi for us! Talked the dealer down to $600. Let’s face it; no one in New England wants a 2WD Jeep. Good news for us.

Windshield cracked no title, 243k miles, chunky brown coolant, but running great, no real rust and fairly straight body. The only bad part is that we couldn’t find a manual transmission XJ. The automatic transmission (AW4) is bulletproof though so it isn’t all bad news.

We started the build with finding our starting weight. Not terribly heavy at all, only 2,865 lbs, and began removing the roof rack, rear seats and other unnecessary items like a/c and heater accessories, wiper motors (front and rear) and radio and speakers. We also gutted the hood and installed pins. Final racing weight in Gainesville was a very respectable 2,677 lbs.

Second step was to find a suitable rear axle. Since they are plentiful, strong, come with disk brakes, limited slip, and have better gearing (3.73 vs. 3.55) the Ford 8.8 out of an Explorer was the perfect solution. $100 for a nasty looking one at a junk yard was the easy part. We then cut the spring perches and re-welded them at the proper width for a Jeep Cherokee but flipped them to the bottom so we could convert to a spring-under layout achieving the rear suspension drop of about 4.5". Used U-Bolts attached the stock Jeep leaf springs to the Ford Axle. A $25 adapter from Spicer made the job of attaching the Ford axle to the stock Jeep drive shaft a breeze.

To increase spring rate we used a second pair of junk sagged stock Cherokee springs and doubled up most of the leaves with the original pack. It gave us more spring rate without increasing ride height.

Finding shocks for a lowered Jeep Cherokee proved to be difficult but after a lot of research on shock lengths and specs, craigslist got us a pair of new Rancho 5000 shocks for a Ford F150 for the front and a pair of used Bilstein shocks off a Toyota Tacoma TRD in the rear. They are both compressed a lot but should do the trick. We may have to look into ways to get more travel out of the system if its purpose expands from just autocross as they would bottom out too quickly for rally-cross duty.

The front axle was much more involved. Since the solid tube front axle could hit the oil pan under full compression we decided to cut and notch it. Having had lifted jeeps in the past we knew the big problems that can arise from changing the angles of the control arms so we needed to address that. The upper and lower control arm brackets on the axle were shortened and lengthened respectively to compensate for the drop in the front. Additionally we made a drop bracket off the axle to use a stock length track rod that still centered the axle after all the changes.

Since offset front ball joints are way to rich for the budget and we were cutting the front axle anyway we decided to notch and bend the front axle for additional camber. After researching more about the front axle modifications the Archer brothers used successfully racing the Jeep Comanche in the SCCA Truck Challenge series we found that they actually bent the front axle. Since we don’t have the facilities to accurately bend it whole, we cut a pie out of the middle leaving a small portion at the bottom intact and stood on it until we ultimately achieved -2.5 degrees static camber on each side.

A great deal on poly front control arm bushings firmed up the axle control and a few sections of steel plate were welded onto the stock control arms to box them in for strength. The new axle modifications clear the oil pan with room to spare and the control arms retain their stock angles.

The driveline was firmed up with poly motor mounts found on eBay for $0.99! They were for a Jeep Wrangler (TJ) so they had to be cut approximately 1” to fit an XJ. We couldn’t find a steal like that on a transmission mount so we injected some polyurethane into the voids in the stock sagged rubber mount and let it cure. What a difference!

Used crusty Addco anti-sway bars were taken off a parted out Jeep and installed front and rear. They’re 1-1/8" front and 7/8" rear. The rear links are poly bushings with washers and a long bolt and we had to fabricate and weld a mounting location onto the rear axle. The stock front links were cut shorter and rewelded to fit the much lower suspension. The combination of cut springs, stiffer shocks and sway bars results in a very stiff vehicle.

#2

Thread Starter

Junior Member

iTrader: (9)

Joined: Apr 2007

Posts: 237

Total Cats: 0

From: Hanover, MA

PART 2 Now the front and rear disc brakes were given some love. New rear hard brake lines were bent up and the stock Jeep rubber hose was attached to the Ford brakes. In the rear the stock rotors were wire wheeled clean and Kool-Vue $7 pads were installed. The front got throw-away rotors and used Duralast Gold pads. The brake lines were bled and everything works well enough. Very surprisingly, and likely the first time ever on a Cherokee, Alan McCrispin described them as 'awesome'... I’m thinking the tire diameter/weight advantage over stock was the largest factor.

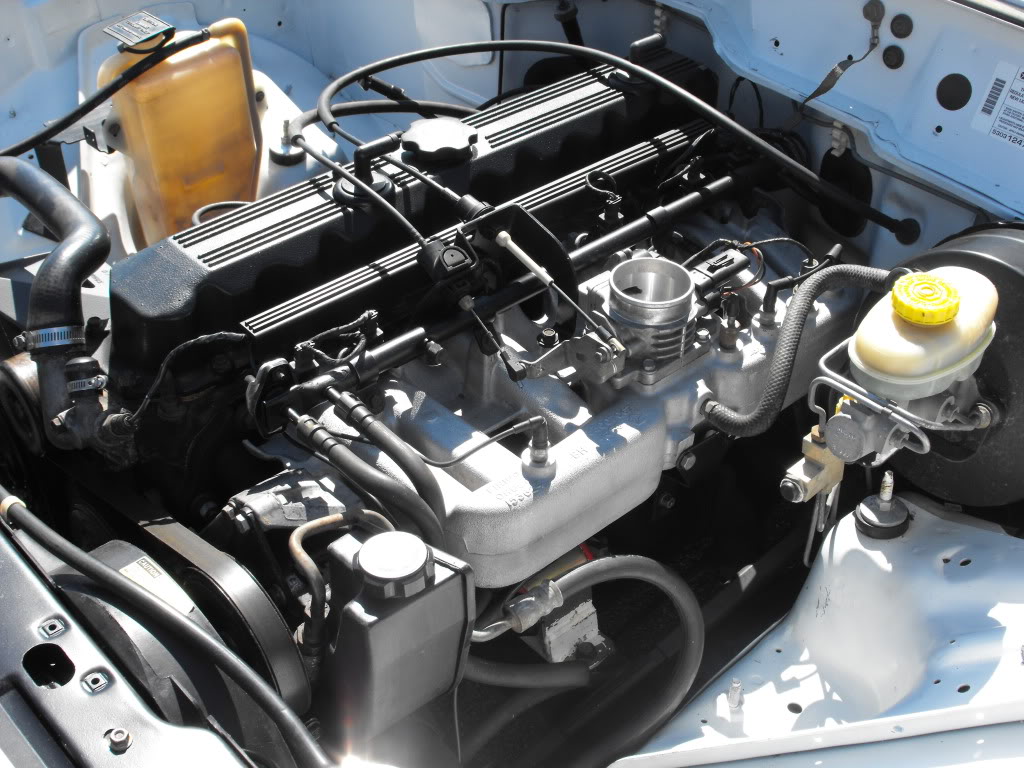

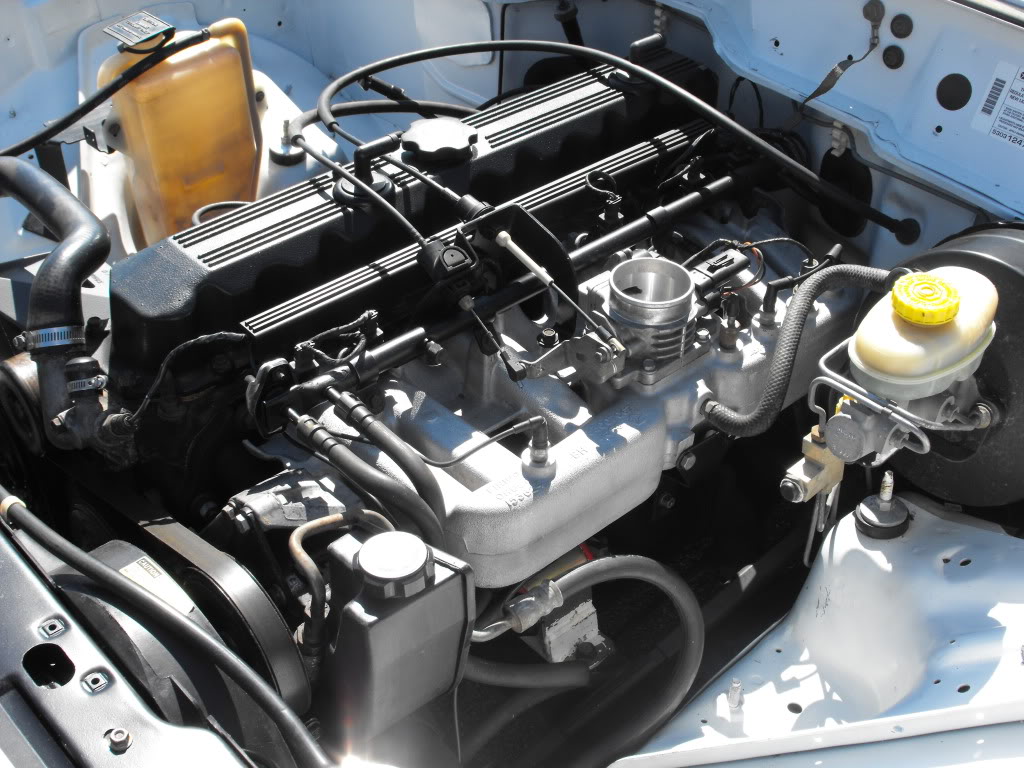

Next up was pulling the engine for a good cleaning. Some degreaser and a pressure washer helped get years of oil leak accumulation off the engine and transmission. A badly leaking valve cover gasket was replaced and the engine was ready to go back in. We also removed the engine bay wiring harness for later and relocated it under the dash to de-ugly the engine bay. Only essential interior wiring was retained and everything was run on the driver’s side along the door sill. Huge holes left in the firewall from the removed blower motor, wiring harness, and HVAC lines were patched and painted.

Next step took us well through the winter: Gutting the stock engine harness and patching in Megasquirt.

There is very little information on wiring Megasquirt into a Jeep so we were mostly on our own here. A factory service manual and many hours later allowed us to cut the wiring harness in half and in theory have Megasquirt running ignition and fuel using the stock distributor's internal hall effect switch with a Ford V6 6-window trigger wheel. After many, many hours of troubleshooting a no-rpm signal issue we removed all jumpers and modifications to Megasquirt only to find that my very first jumper installed was in the wrong hole on one end. Soldered back correctly and viola! With the wiring harness back in the Jeep it came to life on the first try! It ran amazingly well with the baseline tune (modified 1.6L miata turbo tune...) and runs pretty well with more time.

Running gear is a take-off set of 275/35/15 Hoosiers from a local autocrosser that we mounted on 15x10 steel wheels front and rear. The front wheels have a 5" backspace and the rear backspace is 4" as the ford axle is narrower than the original so the front and rear track width and the bulging tire look is roughly equal.

The Jeep needed to look a little more like a proper race car. We decided on a front and rear bumper tuck. The rear bumper is a basic tuck. Caps were welded on the ends and the bumper painted white to match the body.

The front bumper was more involved. We discussed blending the bumper to the existing body work and Dave took that idea and created a really nice contoured bumper. We also cleaned up the stock lower valence and riveted on a strip of aluminum to the back to straighten the wavy piece and add rigity.

The interior also needed a lot of attention. A plastic racing seat was bolted to the stock slider bracket. The stock steering wheel center ring was cut out and a cheap eBay steering wheel was mounted.

Once the interior was gutted we realized that it wasn’t too bad. The basics were clean but since there was some rust on the flood it needed a clean coat of $0.97 Home Depot white spray paint and some truck bed lining in the rear. We also cut up a 4'x8' sheet of gray PVC to cover the holes left by the interior panels.

Next up was pulling the engine for a good cleaning. Some degreaser and a pressure washer helped get years of oil leak accumulation off the engine and transmission. A badly leaking valve cover gasket was replaced and the engine was ready to go back in. We also removed the engine bay wiring harness for later and relocated it under the dash to de-ugly the engine bay. Only essential interior wiring was retained and everything was run on the driver’s side along the door sill. Huge holes left in the firewall from the removed blower motor, wiring harness, and HVAC lines were patched and painted.

Next step took us well through the winter: Gutting the stock engine harness and patching in Megasquirt.

There is very little information on wiring Megasquirt into a Jeep so we were mostly on our own here. A factory service manual and many hours later allowed us to cut the wiring harness in half and in theory have Megasquirt running ignition and fuel using the stock distributor's internal hall effect switch with a Ford V6 6-window trigger wheel. After many, many hours of troubleshooting a no-rpm signal issue we removed all jumpers and modifications to Megasquirt only to find that my very first jumper installed was in the wrong hole on one end. Soldered back correctly and viola! With the wiring harness back in the Jeep it came to life on the first try! It ran amazingly well with the baseline tune (modified 1.6L miata turbo tune...) and runs pretty well with more time.

Running gear is a take-off set of 275/35/15 Hoosiers from a local autocrosser that we mounted on 15x10 steel wheels front and rear. The front wheels have a 5" backspace and the rear backspace is 4" as the ford axle is narrower than the original so the front and rear track width and the bulging tire look is roughly equal.

The Jeep needed to look a little more like a proper race car. We decided on a front and rear bumper tuck. The rear bumper is a basic tuck. Caps were welded on the ends and the bumper painted white to match the body.

The front bumper was more involved. We discussed blending the bumper to the existing body work and Dave took that idea and created a really nice contoured bumper. We also cleaned up the stock lower valence and riveted on a strip of aluminum to the back to straighten the wavy piece and add rigity.

The interior also needed a lot of attention. A plastic racing seat was bolted to the stock slider bracket. The stock steering wheel center ring was cut out and a cheap eBay steering wheel was mounted.

Once the interior was gutted we realized that it wasn’t too bad. The basics were clean but since there was some rust on the flood it needed a clean coat of $0.97 Home Depot white spray paint and some truck bed lining in the rear. We also cut up a 4'x8' sheet of gray PVC to cover the holes left by the interior panels.

#3

Thread Starter

Junior Member

iTrader: (9)

Joined: Apr 2007

Posts: 237

Total Cats: 0

From: Hanover, MA

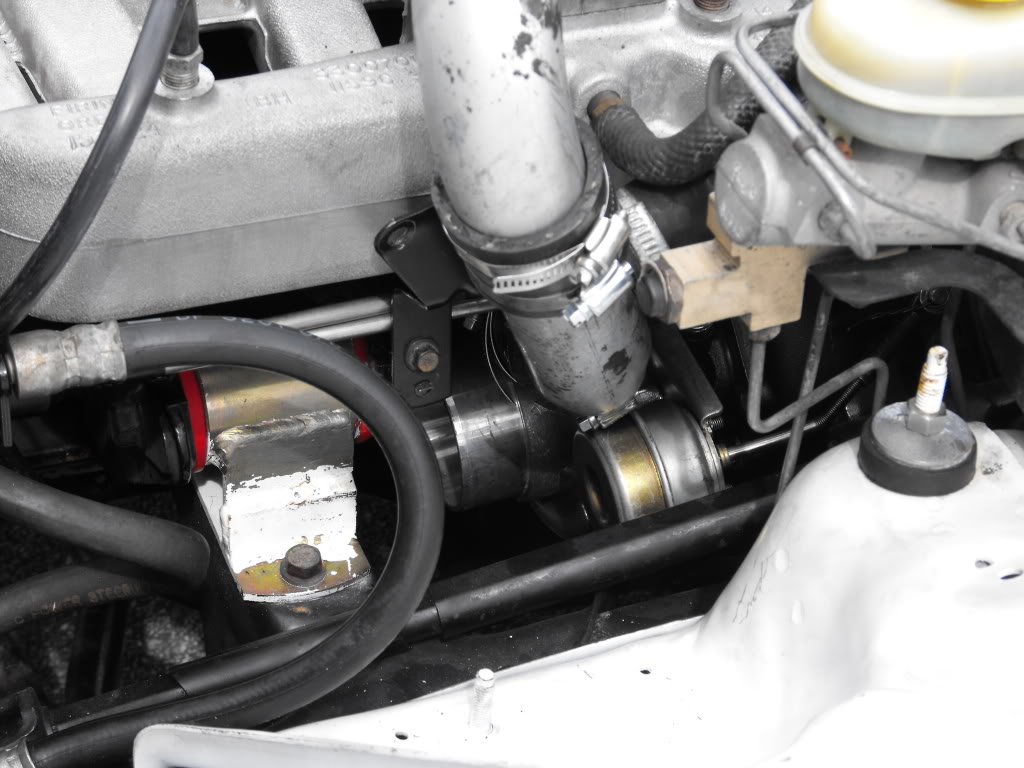

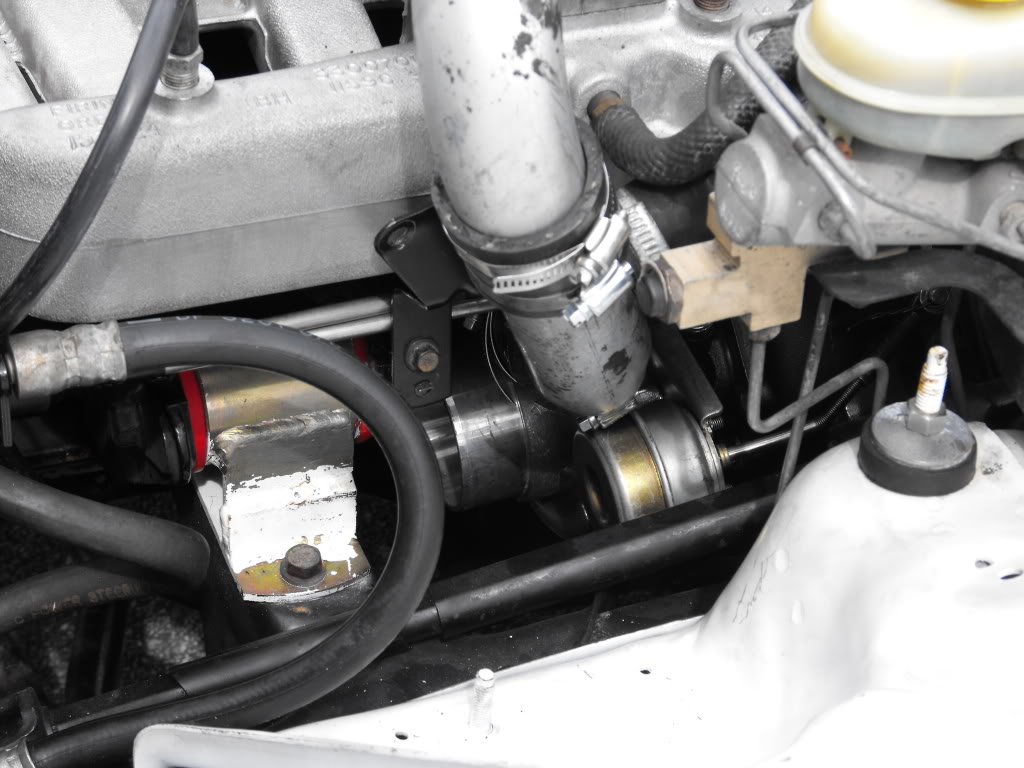

PART 3 Finally last but not least was the turbo. This proved to be the most “interesting” part of the project. A junked Renix (1988) exhaust manifold was cut and re-welded to hang a bit higher. Then a piece of old square basketball hoop pole was cut and used as a spacer to mount the turbo flange too. Then a simple piece of 90 degree bend was welded to the internal waste gate housing to create the down pipe.

In reality we ran out of time to install the turbo before the event. So we packed up the pieces and headed off the Gainesville Florida. Once we were there the rumors started swirling that we might try to install the turbo down there. We decided as a team that it had to be done. Once we got back from a full day of autocrossing and concourse judging it was time to…drink. Then flash forward a few hours and NOW it was time to start installing the turbo. So at around 11 PM we all gathered in the parking lot and started pulling the stock parts off the Jeep and mocking up the turbo parts.

The install lasted into the next day and the 15.5 second ¼ mile run didn’t impress many, but it was all worth it. To be able to install that turbo with my friends under pressure was a blast.

Dave and I want to thank everyone who helped make this a build I will remember for a long time. I especially want to thank Greg, Pat, Tony, and Rob. Without them there is no way this all gets done. Last but not least I need to thank my wife Lindsay for putting up with me and Dave working on the Jeep so many hours and for not complaining about all the spare parts in the basement and race cars in the driveway.

Hopefully we can bring the Jeep back next year with more power.

In reality we ran out of time to install the turbo before the event. So we packed up the pieces and headed off the Gainesville Florida. Once we were there the rumors started swirling that we might try to install the turbo down there. We decided as a team that it had to be done. Once we got back from a full day of autocrossing and concourse judging it was time to…drink. Then flash forward a few hours and NOW it was time to start installing the turbo. So at around 11 PM we all gathered in the parking lot and started pulling the stock parts off the Jeep and mocking up the turbo parts.

The install lasted into the next day and the 15.5 second ¼ mile run didn’t impress many, but it was all worth it. To be able to install that turbo with my friends under pressure was a blast.

Dave and I want to thank everyone who helped make this a build I will remember for a long time. I especially want to thank Greg, Pat, Tony, and Rob. Without them there is no way this all gets done. Last but not least I need to thank my wife Lindsay for putting up with me and Dave working on the Jeep so many hours and for not complaining about all the spare parts in the basement and race cars in the driveway.

Hopefully we can bring the Jeep back next year with more power.

#8

Thread Starter

Junior Member

iTrader: (9)

Joined: Apr 2007

Posts: 237

Total Cats: 0

From: Hanover, MA

We talked about what our next project should be on the way back from the 08 challenge. As a joke we talked about doing a Jeep since no one has ever entered one. Turned out Dave and Jeff were serious and a few months later there was a 2wd Jeep in the driveway.

For the autocross the Jeep was NA. It actually did much better then we thought. One issue we did have was it was lifting a rear wheel and the limited slip was worn out. Since then we have removed the rear sway bar and its now lifting a front wheel. Still need sort the suspension and shim the limited slip.

The 15.5 quarter mile was disappointing. What happened was we lost one of our larger injectors somewhere around 2am the night before. We finished the install 30 minutes before the track closed Sunday and tried running 24 lbs ones but they were way to small. At around 3000 RPMs we were out of fuel at 12 psi. We tried loosening the wastegate to run less boost, leaning the map out to 12:1 but the few laps around the parking lot tuning showed there was not much we could do. We made one light pass with the wastegate open and ran a 17 something then one more with it loose at half throttle and got the 15.5. After that pass the track closed. Hopefully next year we will have it sorted out. I'm shooting for 275-300hp next year and low 13's. I think that's a reasonable goal. We have since removed the turbo kit till we can find bigger injectors and have been autocrossing it with a local BMW club.

Just for an idea my stock 4wd XJ ran 16.3 in the quarter and Dave's with a 4.7L stroker ran mid 15's.

For the autocross the Jeep was NA. It actually did much better then we thought. One issue we did have was it was lifting a rear wheel and the limited slip was worn out. Since then we have removed the rear sway bar and its now lifting a front wheel. Still need sort the suspension and shim the limited slip.

The 15.5 quarter mile was disappointing. What happened was we lost one of our larger injectors somewhere around 2am the night before. We finished the install 30 minutes before the track closed Sunday and tried running 24 lbs ones but they were way to small. At around 3000 RPMs we were out of fuel at 12 psi. We tried loosening the wastegate to run less boost, leaning the map out to 12:1 but the few laps around the parking lot tuning showed there was not much we could do. We made one light pass with the wastegate open and ran a 17 something then one more with it loose at half throttle and got the 15.5. After that pass the track closed. Hopefully next year we will have it sorted out. I'm shooting for 275-300hp next year and low 13's. I think that's a reasonable goal. We have since removed the turbo kit till we can find bigger injectors and have been autocrossing it with a local BMW club.

Just for an idea my stock 4wd XJ ran 16.3 in the quarter and Dave's with a 4.7L stroker ran mid 15's.

#9

Thread Starter

Junior Member

iTrader: (9)

Joined: Apr 2007

Posts: 237

Total Cats: 0

From: Hanover, MA

Quick view of what we were dealing with on our second tuning pass in the parking lot. We got to 4000 RPMS and were all done. We also didn't know what the wategate was rated at so I had it pull a bunch of timing above 8 psi. Also notice the 200+ intake temps, lol. Some heat shielding and an intercooler might be in our future.

Last edited by Pseudosport; 11-15-2010 at 09:41 PM.

#13

MY MEN LET ME START SAYING MY NAME IS RYAN I OWN A XJ , LOOKING FOR MODS ABOUT TURBO I STUMBLE ACROSS YOURE TREAD IN THE MAZDA FORUM, I LOVE THE WORK YOU GUYS DID, IT IMPRESS ME HOW COMPACT YOU MANAGE TO FIT THE TURBO UNDER THE INTAKE

IN THE MAZDA FORUM, I LOVE THE WORK YOU GUYS DID, IT IMPRESS ME HOW COMPACT YOU MANAGE TO FIT THE TURBO UNDER THE INTAKE  YOU CAN'T TELL . I HOPE I CAN GET A HOLD OF YOU TO GATHER SOME INFO , I WANT TO DO SOMETHING SIMILAR TO GET LIKE 8 POUNDS WITHOUT INTERCOOLER FOR REGULAR DRIVING AND POWER FOR THE HILLS WHEN I GO UP STATE I'LL BE GETTING A CRANK AND RODS FROM A 258 TO MAKE IT STROKER TOO SO ANY IMPUT YOU CAN GET ME AND LOTS OF PICS WOULD BE APRECIATED SPECIALY THE MODS OF THE EXAUST TO CONNECT THE TURBO. THANKS I JUST WAIT FOR YOUR RESPONSE

YOU CAN'T TELL . I HOPE I CAN GET A HOLD OF YOU TO GATHER SOME INFO , I WANT TO DO SOMETHING SIMILAR TO GET LIKE 8 POUNDS WITHOUT INTERCOOLER FOR REGULAR DRIVING AND POWER FOR THE HILLS WHEN I GO UP STATE I'LL BE GETTING A CRANK AND RODS FROM A 258 TO MAKE IT STROKER TOO SO ANY IMPUT YOU CAN GET ME AND LOTS OF PICS WOULD BE APRECIATED SPECIALY THE MODS OF THE EXAUST TO CONNECT THE TURBO. THANKS I JUST WAIT FOR YOUR RESPONSE

IN THE MAZDA FORUM, I LOVE THE WORK YOU GUYS DID, IT IMPRESS ME HOW COMPACT YOU MANAGE TO FIT THE TURBO UNDER THE INTAKE

IN THE MAZDA FORUM, I LOVE THE WORK YOU GUYS DID, IT IMPRESS ME HOW COMPACT YOU MANAGE TO FIT THE TURBO UNDER THE INTAKE  YOU CAN'T TELL . I HOPE I CAN GET A HOLD OF YOU TO GATHER SOME INFO , I WANT TO DO SOMETHING SIMILAR TO GET LIKE 8 POUNDS WITHOUT INTERCOOLER FOR REGULAR DRIVING AND POWER FOR THE HILLS WHEN I GO UP STATE I'LL BE GETTING A CRANK AND RODS FROM A 258 TO MAKE IT STROKER TOO SO ANY IMPUT YOU CAN GET ME AND LOTS OF PICS WOULD BE APRECIATED SPECIALY THE MODS OF THE EXAUST TO CONNECT THE TURBO. THANKS I JUST WAIT FOR YOUR RESPONSE

YOU CAN'T TELL . I HOPE I CAN GET A HOLD OF YOU TO GATHER SOME INFO , I WANT TO DO SOMETHING SIMILAR TO GET LIKE 8 POUNDS WITHOUT INTERCOOLER FOR REGULAR DRIVING AND POWER FOR THE HILLS WHEN I GO UP STATE I'LL BE GETTING A CRANK AND RODS FROM A 258 TO MAKE IT STROKER TOO SO ANY IMPUT YOU CAN GET ME AND LOTS OF PICS WOULD BE APRECIATED SPECIALY THE MODS OF THE EXAUST TO CONNECT THE TURBO. THANKS I JUST WAIT FOR YOUR RESPONSE

Classic Wal-Mart

Classic Wal-Mart