HyperMiata's 2017 Splitter

#1

Thread Starter

Joined: Jul 2006

Posts: 3,304

Total Cats: 1,225

From: San Diego

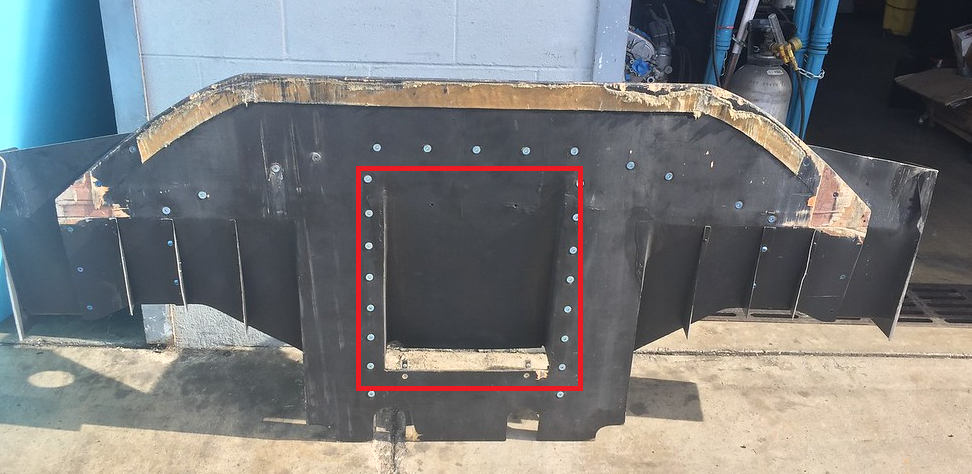

Sharing these pics of the Splitter I ran for the 2017 season and a couple events in 2018, including winning Superlap Battle by a margin of 3 seconds. Some of this was experimental, I'm not offering these pics as suggestion that others should copy what I did in every way.

After two years of abuse it has the scrapes to show for it, but there's no necessity to retire it. This splitter has been a workhorse, still performing well at the most recent GTA ProAm round where we won yet again.

Construction is birch ply with a top layer of carbon fiber with epoxy resin (same sealing effect as fiberglass just more bling). I bonded a strip of kevlar along the lower leading edge to help with durability - eventually I wore through that as well but at a much slower rate than the birch. After the kevlar I designed disposable slider "pucks" made from delrin which I added in a couple places along the front edge and at the outer corners to prevent contact of the main splitter with the ground. The pucks get discarded when they wear to about 25% thickness. After testing these pucks for over a year, this will be a new product coming soon from Singular Motorsports.

The center diffuser is the thing most people didn't know about and wasn't easily visible when mounted. The air vented up and over the steering rack into the engine bay (further adding to the need for as much venting in the hood as possible), a very high-drag way to try to make as much downforce as possible out of the surface area I had available. Also, lots of dirt in the engine bay.

The side extensions were added for SLB 2017. Simple, just increasing surface area, and the large fence on the rear edge encouraged a build up of pressure there. Again, draggy but effective.

NACA ducts supplied the 3" brake duct hose with air.

The frame has been through about 5 revisions, but has always been a solid-mount design. I disagree with all of the arguments for tear-away concepts. This splitter has been through a lot, and it probably wouldn't still be here and wouldn't have been as successful if it had been designed to be ejected in certain situations /rant. Most of the mounting hardware is countersunk into the birch for less airflow disturbance.

Another bit we didn't really share was that the splitter was rake adjustable. There were plenty of academic discussions floating around about what angle splitters perform best at (generally an argument between level vs. slight positive rake) but I had never heard of anyone doing real testing of these options. Making the setup quickly rake adjustable trackside made the mounting far more complicated, so I did it so that you don't have to. We had an adjustment range of 3.5° with small 0.25° increments. The natural ~1/4" rake of a Miata translates to about 0.5° of splitter rake if the splitter is set up to be parallel with the chassis. I found the splitter to perform best between that natural 0.5° and 1° of rake (i.e. splitter angled 0.5° down from chassis plane), but no more.

After two years of abuse it has the scrapes to show for it, but there's no necessity to retire it. This splitter has been a workhorse, still performing well at the most recent GTA ProAm round where we won yet again.

Construction is birch ply with a top layer of carbon fiber with epoxy resin (same sealing effect as fiberglass just more bling). I bonded a strip of kevlar along the lower leading edge to help with durability - eventually I wore through that as well but at a much slower rate than the birch. After the kevlar I designed disposable slider "pucks" made from delrin which I added in a couple places along the front edge and at the outer corners to prevent contact of the main splitter with the ground. The pucks get discarded when they wear to about 25% thickness. After testing these pucks for over a year, this will be a new product coming soon from Singular Motorsports.

The center diffuser is the thing most people didn't know about and wasn't easily visible when mounted. The air vented up and over the steering rack into the engine bay (further adding to the need for as much venting in the hood as possible), a very high-drag way to try to make as much downforce as possible out of the surface area I had available. Also, lots of dirt in the engine bay.

The side extensions were added for SLB 2017. Simple, just increasing surface area, and the large fence on the rear edge encouraged a build up of pressure there. Again, draggy but effective.

NACA ducts supplied the 3" brake duct hose with air.

The frame has been through about 5 revisions, but has always been a solid-mount design. I disagree with all of the arguments for tear-away concepts. This splitter has been through a lot, and it probably wouldn't still be here and wouldn't have been as successful if it had been designed to be ejected in certain situations /rant. Most of the mounting hardware is countersunk into the birch for less airflow disturbance.

Another bit we didn't really share was that the splitter was rake adjustable. There were plenty of academic discussions floating around about what angle splitters perform best at (generally an argument between level vs. slight positive rake) but I had never heard of anyone doing real testing of these options. Making the setup quickly rake adjustable trackside made the mounting far more complicated, so I did it so that you don't have to. We had an adjustment range of 3.5° with small 0.25° increments. The natural ~1/4" rake of a Miata translates to about 0.5° of splitter rake if the splitter is set up to be parallel with the chassis. I found the splitter to perform best between that natural 0.5° and 1° of rake (i.e. splitter angled 0.5° down from chassis plane), but no more.

#2

I'm sure that delrin is cheaper, but Pegasus sells stuff to be used as sacrificial material specifically for what you're decribing, if that's helpful in any way for you?

https://www.pegasusautoracing.com/pr...p?Product=6180

https://www.pegasusautoracing.com/pr...p?Product=6180

#3

Thread Starter

Joined: Jul 2006

Posts: 3,304

Total Cats: 1,225

From: San Diego

I'm sure that delrin is cheaper, but Pegasus sells stuff to be used as sacrificial material specifically for what you're decribing, if that's helpful in any way for you?

https://www.pegasusautoracing.com/pr...p?Product=6180

https://www.pegasusautoracing.com/pr...p?Product=6180

#8

Thread Starter

Joined: Jul 2006

Posts: 3,304

Total Cats: 1,225

From: San Diego

Bigger is not necessarily better. Shallow is good, you know you'll maintain flow attachment. Especially if the construction method necessitates a sharp angle change at the throat, going too steep is the quickest way to make sure the splitter is even less effective than just being flat.

It should come as no surprise that the new splitter at ~10-15x the cost and ~10x the development time of the old one is on a whole different level.. but that development time is really critical when pushing the boundaries of what works. In other words, a wild splitter can have more performance potential, but going wild also comes with a bigger risk of getting it wrong.

It should come as no surprise that the new splitter at ~10-15x the cost and ~10x the development time of the old one is on a whole different level.. but that development time is really critical when pushing the boundaries of what works. In other words, a wild splitter can have more performance potential, but going wild also comes with a bigger risk of getting it wrong.

#10

The only thing that stands out to me is the acorn nuts on the guide plane extensions (for lack of a better term). I am not sure the constraints with using carbon fiber and selecting hardware but some T-nuts on the bottom side would allow you to use some countersunk hardware on top with little intrusion below, possibly even none if you are able to counter sink the T-nut with a router bit or something. Again, carbon fiber is not something I am versed in working with so that might come off as completely ignorant. Thanks for sharing your work though, your car has been a big influence on many of the directions I have taken with mine.

Just some random photo I pulled.

#11

Thread Starter

Joined: Jul 2006

Posts: 3,304

Total Cats: 1,225

From: San Diego

The underside is where the airflow matters far more. That's why the bolts underneath are countersunk into the splitter with the nuts on top. Consider that in this particular case, the aero strategy just 6 inches away from those nuts is to put a giant endplate and rear fence to block the airflow path, slow the air down in the area where those nuts are, and generate high pressure there. Because of that, those nuts are sitting inside a high pressure pocket where their presence just doesn't make any difference.

With a simpler splitter that didn't have endplates on the side, then yes you'd want to be mindful of protrusions on the topside of the splitter because the air moving laterally around the bumper would be fast-moving and disturbances like the nuts could create little vortices that would contribute a small bit of drag.

With a simpler splitter that didn't have endplates on the side, then yes you'd want to be mindful of protrusions on the topside of the splitter because the air moving laterally around the bumper would be fast-moving and disturbances like the nuts could create little vortices that would contribute a small bit of drag.

#12

With a simpler splitter that didn't have endplates on the side, then yes you'd want to be mindful of protrusions on the topside of the splitter because the air moving laterally around the bumper would be fast-moving and disturbances like the nuts could create little vortices that would contribute a small bit of drag.

#17

The oil cooler in Vegas is horizontal just in front of the steering rack. It is above the 10mm alumilite under tray, protected pretty well. No ducts or openings below it. It's fed by air coming through the nose then exiting into the engine bay. It's been off road twice without harm. Oil temps are always below 220° at 420whp.

Point is that oil cooler location can be secure with some planning. Ryan's can be made to work well and still be safe with some revisions

Point is that oil cooler location can be secure with some planning. Ryan's can be made to work well and still be safe with some revisions

__________________